With years of extensive experience in power system supply, SinoMac Group is capable of quickly understanding and responding to customer needs, significantly reducing communication costs for clients. The company offers a one-stop solution that covers everything from pre-design to component supply, from installation to commissioning, and from pre-sales communication to after-sales service support….

SinoMac also gradually building our global services network, from branch companies to joint ventures, from local sales representatives to local after-sales services partners, we continuously expanding our global network to provide better communication and services for our customers.

Till 2021, SinoMac has branch companies and joint ventures in Thailand and Singapore, we also have after-sales service ability in these two countries. We have sales representatives in Turkey, Spain, France, and the UK….

SinoMac Group is an excellent solution provider with a professional and dedicated team. We have developed an advanced management system based on our past experiences, and SinoMac Group is an innovator in detailed visualization services, offering professional videos for every single product we sell. This commitment to excellence ensures that our customers receive not only high-quality products but also unparalleled service and support. …

With the mission of “Better Power, Better World”, and the vision of “Make China Power the World”, SinoMac looking for business partners in each country, that can working both as branch company or joint venture, by utilize the rich resources here in China, and our local business partner’s network resource and local service advantages, we hope can help all manufacturers in the world to improve their design ability, manufacturing capability, management level and products quality standard….

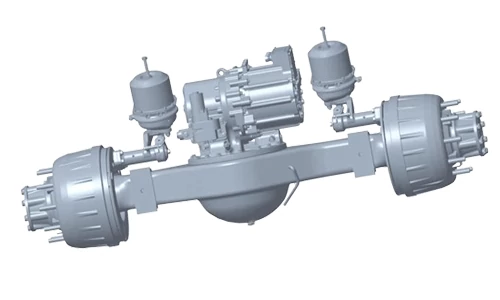

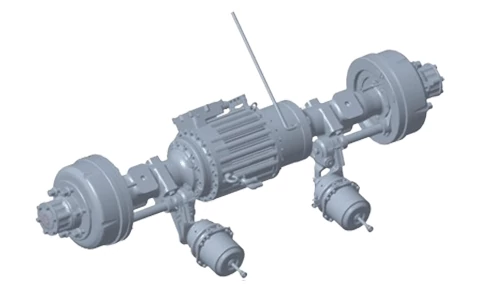

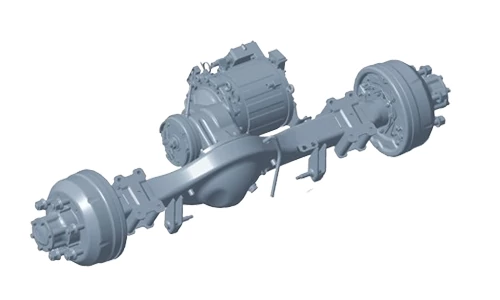

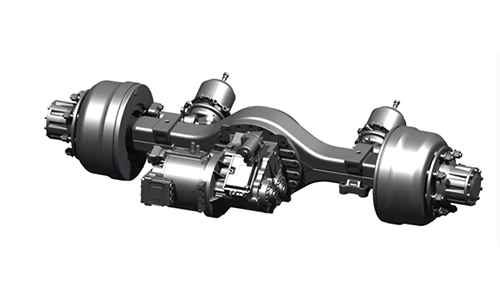

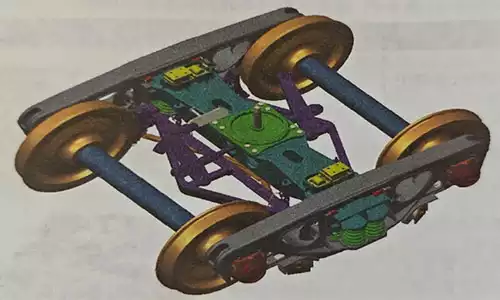

Areas of Application for Electric Driven Axle

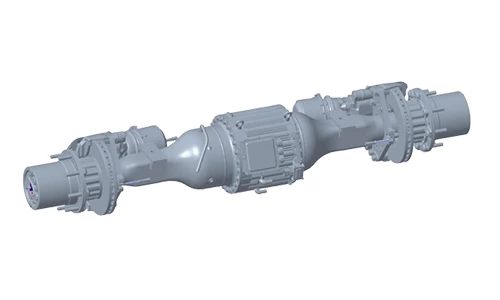

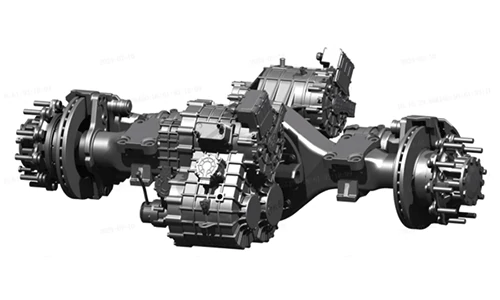

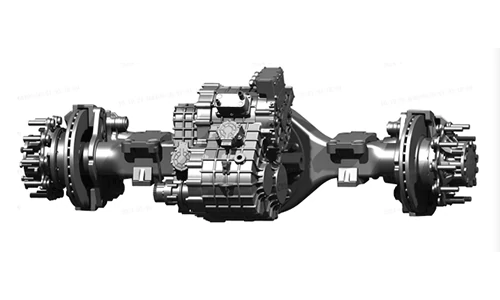

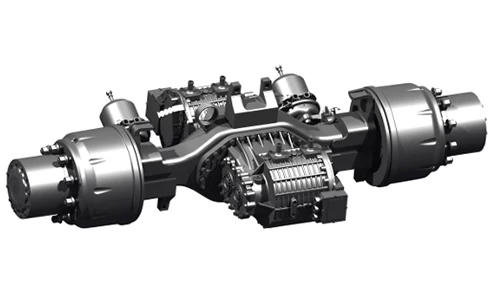

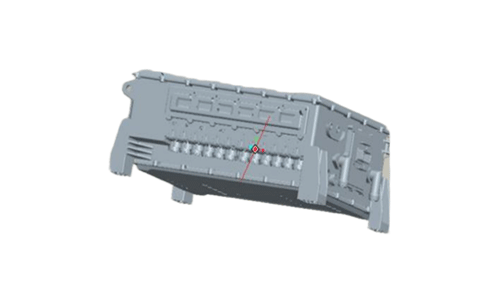

Electric drive axle is a fully developed new series of products, used in intercity buses, trucks etc. Adopting external motor,which is integrated with the axle retarder, having smooth traveling, strong power and reliable performance.

Including: EP5|EP6|EP13|EP19

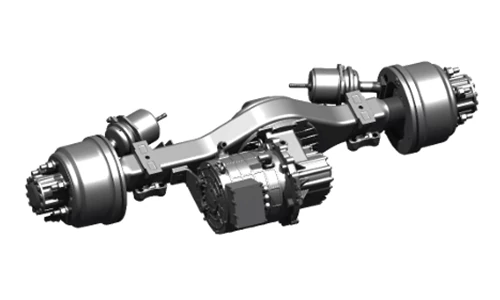

New Energy Electric Driven Axle Applications

Including: QT20PE, QT30PE, QT35/ 45PE, QT60PE, QT60SPE, QT80SPE etc.

The Leader in Driven Motors

Including:TZ180, TZ220, TZ260, TZ290, TZ380, TZ400, TZ460 etc.

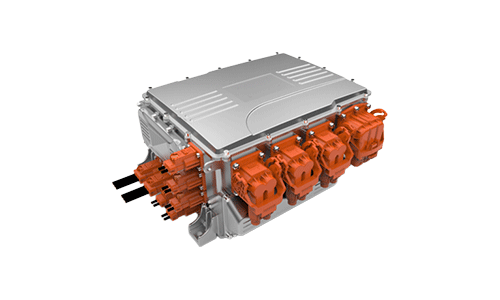

Controller for Integrated System Design

Including: SA Series Single Motor Controller, DA Series Dual Motor Controller, DC180 Dual-Motor Controller etc.

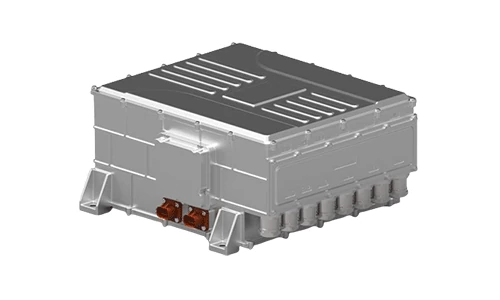

Power Battery Usage

Including: A21, A22, A24, A25, A27-V1, L11, LF125H, M12 etc.

Find Engines by Series or Type

Below list is the engines classified by engine type, you can also find engines classified by series in the top menu.

Electric Driven Alxe

| 3500 – 13000 kg | ||||||||

| 3500 – 13000 kg | ||||||||

| 2 – 13 T | ||||||||

Engine Model Load/kg | 0 | 2000 | 4000 | 8000 | 10000 | 12000 | 14000 | 16000 |

| Electric Driven Alxe Catalogue | ||||||||

Rated Load : 13000 kg Rated Load : 3500 kg Rated Load : 3500 kg EP-Axle28D Truck

Maximum Torque : 28000 N.m

Speed Ratio : 54.32 / 18.72

Motor Voltage : 540 V EP-Axle6 Truck

Maximum Torque : 5700 N.m

Speed Ratio : 16.5

Motor Voltage : 360 / 540 V EP-Axle5 Truck

Maximum Torque : 5400 N.m

Speed Ratio : 15.58

Motor Voltage : 360 / 540 V

Rated Load : 13000 kg Rated Load : 13000 kg Rated Load : 8500 kg Rated Load : 3500 kg Rated Load : 3500 kg EP-Axle19C2 Passenger Car

Maximum Torque : 19256 N.m

Speed Ratio : 25.338

Motor Voltage : 540 V EP-Axle19C Passenger Car

Maximum Torque : 18000 N.m

Speed Ratio : 20.05

Motor Voltage : 650 / 576 V EP-Axle13 Passenger Car

Maximum Torque : 13000 N.m

Speed Ratio : 19.89

Motor Voltage : 380 V EP-Axle6 Passenger Car

Maximum Torque : 5700 N.m

Speed Ratio : 16.5

Motor Voltage : 360 / 540 V EP-Axle5 Passenger Car

Maximum Torque : 5400 N.m

Speed Ratio : 15.58

Motor Voltage : 360 / 540 V

Rated Axle Load : 13 T Rated Axle Load : 13 T Rated Axle Load : 11.5 ~ 13 T Rated Axle Load : 11.5 T Rated Axle Load : 11.5 T Rated Axle Load : 8 T Rated Axle Load : 6 T Rated Axle Load : 6 T Rated Axle Load : 3.5 ~ 4.5 T Rated Axle Load : 3 T Rated Axle Load : 2 T QT130SPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1054 mm

Total Speed Ratio : 56.7 / 23.5 / 46 / 19 QT130STPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1040 mm

Total Speed Ratio : 56.6 / 32 / 16.7 QT115SPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1040 mm

Total Speed Ratio : 75 / 38 / 20.8 QT115DTPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1040 mm

Total Speed Ratio : 14.5 QT115TPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1030 mm

Total Speed Ratio : 14.5 QT80SPE

End Face Distance : 1804 mm

Leaf Spring Distance : 1030 mm

Total Speed Ratio : 31.1 / 16.3 QT60SPE

End Face Distance : 1615 mm

Leaf Spring Distance : 940 mm

Total Speed Ratio : 28.202 / 11.379 QT60PE

End Face Distance : 1615 mm

Leaf Spring Distance : 940 mm

Total Speed Ratio : 16.5 QT30-45PE

End Face Distance : 1640 ~ 1495 mm

Leaf Spring Distance : 920 / 970 mm

Total Speed Ratio : 16.1 QT30PE

End Face Distance : 1470 mm

Leaf Spring Distance : 900 mm

Total Speed Ratio : 14.3 QT20PE

End Face Distance : 1535 mm

Leaf Spring Distance : 1080 mm

Total Speed Ratio : 14

Driven Motor

Engine Model Power/kW25-70 kW 25-70 kW 75 kW 60-100 kW 120-215 kW 120-215 kW 45-100 kW 0 50 100 150 200 250 300 350 Drive Motor Catalogue

Volt : 540 VDC Volt : 320 VDC Volt : 618 VDC Volt : 350 VDC Volt : 540 VDC Volt : 540 VDC Volt : 320 VDC Volt : 540 VDC Volt : 350 VDC Volt : 640 VDC Volt : 540 VDC Volt : 360 VDC Volt : 540 VDC Volt : 540 VDC Volt : 540 VDC Volt : 540 VDC Volt : 600 VDC Volt : 600 VDC Volt : 540 VDC Volt : 540 VDC Volt : 500 VDC Volt : 540 VDC Volt : 540 VDC Volt : 5400 VDC Volt : 450 VDC Volt : 540 VDC Volt : 600 VDC Volt : 618 VDC Volt : 600 VDC Volt : 540 VDC The relevant products still under developing or waiting to be update, please contact our sales team for latest updates. TZ180XS017A

Rated / Prak Power : 20 / 40 kw

Rated / Peak Torque : 150 / 300 Nm

Rated / Peak RPM : 1273 / 2400 RPM TZ180XS009-II

Rated / Prak Power : 30 / 60 kw

Rated / Peak Torque : 100 / 225 Nm

Rated / Peak RPM : 2865 / 9000 RPM TZ180XS009-I

Rated / Prak Power : 60 / 125 kw

Rated / Peak Torque : 120 / 200 Nm

Rated / Peak RPM : 4775 / 7500 RPM TZ180XS014E

Rated / Prak Power : 40 / 75 kw

Rated / Peak Torque : 48 / 130 Nm

Rated / Peak RPM : 8100 / 12000 RPM TZ220XS017A

Rated / Prak Power : 60 / 80 kw

Rated / Peak Torque : 360 / 560 Nm

Rated / Peak RPM : 1600 / 2400 RPM TZ220XS020A

Rated / Prak Power : 32.5 / 70 kw

Rated / Peak Torque : 225 / 450 Nm

Rated / Peak RPM : 2860 / 6500 RPM TZ220XS028A

Rated / Prak Power : 30 / 60 kw

Rated / Peak Torque : 100 / 225 Nm

Rated / Peak RPM : 8100 / 12000 RPM TZ220XS026A

Rated / Prak Power : 70 / 145 kw

Rated / Peak Torque : 150 / 330 Nm

Rated / Peak RPM : 4450 / 12000 RPM TZ220XS013A

Rated / Prak Power : 60 / 130 kw

Rated / Peak Torque : 140 / 32 Nm

Rated / Peak RPM : 4000 / 12000 RPM TZ260XS002A

Rated / Prak Power : 90 / 165 kw

Rated / Peak Torque : 300 / 600 Nm

Rated / Peak RPM : 2860 / 10000 RPM TZ290XS027A

Rated / Prak Power : 110 / 190 kw

Rated / Peak Torque : 450 / 900 Nm

Rated / Peak RPM : 2400 / 7500 RPM TZ290XS022B

Rated / Prak Power : 70 / 120 kw

Rated / Peak Torque : 445 / 1100 Nm

Rated / Peak RPM : 1500 / 4500 RPM TZ290XS024B

Rated / Prak Power : 70 / 120 kw

Rated / Peak Torque : 445 / 1100 Nm

Rated / Peak RPM : 1500 / 4500 RPM TZ290XS010

Rated / Prak Power : 80 / 150 kw

Rated / Peak Torque : 230 / 650 Nm

Rated / Peak RPM : 3320 / 10000 RPM TZ290XS036A

Rated / Prak Power : 70 / 150 kw

Rated / Peak Torque : 225 / 450 Nm

Rated / Peak RPM : 2971 / 10000 RPM TZ290XS017C

Rated / Prak Power : 77.5 / 150 kw

Rated / Peak Torque : 238 / 554 Nm

Rated / Peak RPM : 3118 / 7500 RPM TZ380XS017J

Rated / Prak Power : 250 / 410 kw

Rated / Peak Torque : 1750 / 2800 Nm

Rated / Peak RPM : 1364 / 3500 RPM TZ380XS017G

Rated / Prak Power : 250 / 360 kw

Rated / Peak Torque : 1405 / 2500 Nm

Rated / Peak RPM : 1700 / 3500 RPM TZ380XS016H

Rated / Prak Power : 120 / 240 kw

Rated / Peak Torque : 1200 / 2500 Nm

Rated / Peak RPM : 955 / 3500 RPM TZ380XS016L

Rated / Prak Power : 120 / 240 kw

Rated / Peak Torque : 1200 / 2800 Nm

Rated / Peak RPM : 955 / 3000 RPM TZ380XS029C

Rated / Prak Power : 150 / 240 kw

Rated / Peak Torque : 850 / 1400 Nm

Rated / Peak RPM : 1685 / 5000 RPM TZ380XS029B

Rated / Prak Power : 160 / 270 kw

Rated / Peak Torque : 750 / 1310 Nm

Rated / Peak RPM : 2038 / 5000 RPM TZ380XS024B-II

Rated / Prak Power : 90 / 180 kw

Rated / Peak Torque : 900 / 2100 Nm

Rated / Peak RPM : 955 / 3500 RPM TZ380XS024B-I

Rated / Prak Power : 85 / 170 kw

Rated / Peak Torque : 850 / 1800 Nm

Rated / Peak RPM : 955 / 3500 RPM TZ380XS027C

Rated / Prak Power : 115 / 180 kw

Rated / Peak Torque : 550 / 1200 Nm

Rated / Peak RPM : 2000 / 4000 RPM TZ380XS027B

Rated / Prak Power : 100 / 150 kw

Rated / Peak Torque : 500 / 1000 Nm

Rated / Peak RPM : 1910 / 3500 RPM TZ400XS015B

Rated / Prak Power : 250 / 360 kw

Rated / Peak Torque : 1600 / 2500 Nm

Rated / Peak RPM : 1500 / 3500 RPM TZ400XS009A

Rated / Prak Power : 200 / 260 kw

Rated / Peak Torque : 1140 / 3000 Nm

Rated / Peak RPM : 1675 / 3300 RPM TZ400XS013A

Rated / Prak Power : 250 / 410 kw

Rated / Peak Torque : 1750 / 2800 Nm

Rated / Peak RPM : 1364 / 3500 RPM TZ400XS010A

Rated / Prak Power : 100 / 200 kw

Rated / Peak Torque : 1061 / 2500 Nm

Rated / Peak RPM : 900 / 2400 RPMProducts Not Available

Power Battery

Standard Voltage : 3.66 V Standard Voltage : 3.66 V Standard Voltage : 3.66 V Standard Voltage : 3.74 V Standard Voltage : 3.22 V Standard Voltage : 3.22 V Standard Voltage : 3.22 V Standard Voltage : 3.22 V Standard Voltage : 3.21 V Standard Voltage : 3.20 V Standard Voltage : 3.20 V Standard Voltage : 3.22 V Standard Voltage : 3.22 V M43 Battery

Standard Capacity : 5.45 Ah

Weight : 189 ± 5 g

Dimensions : 12.6 * 120.2 * 69.2 mm M42 Battery

Standard Capacity : 15 Ah

Weight : 426 ± 7 g

Dimensions : 17.7 * 148.7 * 78.8 mm M41 Battery

Standard Capacity : 19.5 Ah

Weight : 547 ± 15 g

Dimensions : 17.7 * 148.7 * 98.8 mm M12 Battery

Standard Capacity : 188 Ah

Weight : 2896 ± 50 g

Dimensions : 50.6 * 301.3 * 88.6 mm LF125H Battery

Standard Capacity : 125 Ah

Weight : 2310 ± 69 g

Dimensions : 47.7 * 200.7 * 115 mm L11 Battery

Standard Capacity : 154 Ah

Weight : 2755 ± 10 g

Dimensions : 33.7 * 346.4 * 110 mm A41 Battery

Standard Capacity : 106 Ah

Weight : 1880 ± 30 g

Dimensions : 52.2 * 148.6 * 118.5 mm A27-V2.1 Battery

Standard Capacity : 124.9 Ah

Weight : 2240 ± 30 g

Dimensions : 37.2 * 309.5 * 88 mm A27-V1 Battery

Standard Capacity : 127.2 Ah

Weight : 2220 ± 30 g

Dimensions : 37.2 * 309.5 * 88 mm A25 Battery

Standard Capacity : 132.2 Ah

Weight : 2281 ± 35 g

Dimensions : 30.5 * 314 * 17 mm A24 Battery

Standard Capacity : 172 Ah

Weight : 3160 ± 40 g

Dimensions : 36.7 * 301 * 132.5 mm A22 Battery

Standard Capacity : 178.1 Ah

Weight : 3170 ± 30 g

Dimensions : 61 * 281.1 * 88. mm A21 Battery

Standard Capacity : 154 Ah

Weight : 2755 ± 30 g

Dimensions : 33.7 * 346.4 * 110 mm

Motor Controller

Engine Model Power/kW250 – 420 V 250 - 750 V DC 450 - 750 V 330 - 440 VAC DC 250 - 750 V DC 250 - 750 V 400 - 750 V 0 150 250 350 450 550 650 750 Motor Controller Catalogue

Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 250 ~ 420 V Rated Input Voltage : 250 ~ 420 V Rated Input Voltage : 250 ~ 420 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 400 ~ 750 V Rated Input Voltage : 250 ~ 420 V Input Voltage Range : DC 250 ~ 750 V Rated Power :132 kw Input Voltage Range : 330 ~ 440VAC Rectifier Rated Power :160 kw Rectifier Rated Output Current : 380 A Input Voltage Range: DC 450 V ~ 750 V SA500 Controller

Rated Current : 480 A

Peak Output Voltage : 380 Vac

Peak Current : 850 A SA360 Controller

Rated Current : 400 A

Peak Output Voltage : 380 Vac

Peak Current : 620 / 700 A SA220 Controller

Rated Current : 300 A

Peak Output Voltage : 380 Vac

Peak Current : 570 A SA150C Controller

Rated Current : 176 A

Peak Output Voltage : 380 Vac

Peak Current : 350 A SA150B Controller

Rated Current : 230 A

Peak Output Voltage : 380 Vac

Peak Current : 420 A SA150A Controller

Rated Current : 230 A

Peak Output Voltage : 237 Vac

Peak Current : 460 A SA50B Controller

Rated Current : 140 A

Peak Output Voltage : 237 Vac

Peak Current : 330 A SA50A Controller

Rated Current : 120 A

Peak Output Voltage : 237 Vac

Peak Current : 270 A DA500 Controller

Rated Current : 305 A

Peak Output Voltage : 380 Vac

Peak Current : 530 A DA360D Controller

Rated Current : 230 / 305 A

Peak Output Voltage : 380 Vac

Peak Current : 420 / 530 A DA360C Controller

Rated Current : 230 A

Peak Output Voltage : 380 Vac

Peak Current : 420 A DA360B Controller

Rated Current : 160 / 305 A

Peak Output Voltage : 380 Vac

Peak Current : 300 / 530 A DA360A Controller

Rated Current : 160 / 230 A

Peak Output Voltage : 380 Vac

Peak Current : 300 / 420 A DA220 Controller

Rated Current : 176 A

Peak Output Voltage : 380 Vac

Peak Current : 350 A DC180B Controller

Rated Current : 108 A

Peak Output Voltage : 380 Vac

Peak Current : 175 A DC180A Controller

Rated Current : 120 ~ 200 A

Peak Output Voltage : 237 Vac

Peak Current : 270 ~ 400 A M04 Auxiliary Drive Multi-in-One-I

Output Voltage : 27.5 VDC

Power Rating : 3 / 5 kw @ 24 V

Rated Current : 110 / 180 A M15 Main Drive Multi-in-One-I

Peak Power :198 kw

Rated AC Output Current : 205 A

Control Box Protection Level : IP67 Car Inverter Water Cooling V1

Inverter Rated Power : 132 kw Double Main Drive Six-In-One-I

Output Volts: 27.5 VDC

Power Rating: 3 / 5 kw @ 24 V

Rated Current: 110 / 180 A

Customer Review

USA | Construction – A USA Company’s Feedback

EMAC company till now, and EMAC provides us a very good support, no matter pre-sales support or after-sales support. They have deep network of power system manufacturers in China, and ensuring them the strong ability of giving multiple brands options, we are happy to be partner of EMAC, that able to provide us one-stop power system solution from China, and they always can give us best value for money solution based on our requirement...

Indonesia | Construction – Customer lnterview

EMAC's customer interview video of 2025, EMAC finished a series of customer interview with 10 different business partners from different countries and regions, most of videos are took at customer's company and factory, collecting all reviews and evaluations of EMAC, covering different industries in different country and regions, we believe this series of EMAC customer interview videos can help all of other customers get to know more about EMAC, our true customer interview case can greatly help customers relieve their worries, and build their confidence to cooperate with EMAC. A Promise is A Promise, EMAC always do what we say, and for customer’s feedback, also 100% original from clients’s real words. EMAC, a Chinese company that you can trust!

Vietnam | Pump – Electric Motor

EMAC's customer interview video of 2024, EMAC finished a series of customer interview with 10 different business partners from different countries and regions, most of videos are took at customer's company and factory, collecting all reviews and evaluations of EMAC, covering different industries in different country and regions, we believe this series of EMAC customer interview videos can help all of other customers get to know more about EMAC, our true customer interview case can greatly help customers relieve their worries, and build their confidence to cooperate with EMAC. A Promise is A Promise, EMAC always do what we say, and for customer’s feedback, also 100% original from clients’s real words. EMAC, a Chinese company that you can trust!

Thailand | Pump – Equipment Production

EMAC's customer interview video of 2023, EMAC finished a series of customer interview with 10 different business partners from different countries and regions, most of videos are took at customer's company and factory, collecting all reviews and evaluations of EMAC, covering different industries in different country and regions, we believe this series of EMAC customer interview videos can help all of other customers get to know more about EMAC, our true customer interview case can greatly help customers relieve their worries, and build their confidence to cooperate with EMAC. A Promise is A Promise, EMAC always do what we say, and for customer’s feedback, also 100% original from clients’s real words. EMAC, a Chinese company that you can trust!

Indonesia | Marine – Indonesia Shipyard Interview

EMAC's customer interview video of 2023, EMAC finished a series of customer interview with 10 different business partners from different countries and regions, most of videos are took at customer's company and factory, collecting all reviews and evaluations of EMAC, covering different industries in different country and regions, we believe this series of EMAC customer interview videos can help all of other customers get to know more about EMAC, our true customer interview case can greatly help customers relieve their worries, and build their confidence to cooperate with EMAC.

Thailand | Pump – Thailand Engineering Company Interview

EMAC's customer interview video of 2023, EMAC finished a series of customer interview with 10 different business partners from different countries and regions, most of videos are took at customer's company and factory, collecting all reviews and evaluations of EMAC, covering different industries in different country and regions, we believe this series of EMAC customer interview

-

Review SAUDI RAIL 2025 :SinoMac Exhibition Highlights

SinoMac successfully participated in SAUDI RAIL 2025, the annual industry event held in Riyadh, Saudi Arabia, from October 19th to 20th, 2025. At the exhibition, SinoMac showcased its strong capabilities in railway technology, innovative solutions, and full lifecycle services, and engaged in in-depth exchanges with industry partners, customers, and experts from around the world to jointly explore future opportunities for rail transit development in the Middle East.

-

Deeply Cultivate the International Market, Empowering the Future of Rail ——Focus [PRO//Motion Expo 2025]: SinoMac Exhibition Highlights Review

From August 28 to 31, 2025, the highly anticipated PRO//Motion Expo 2025 (Russian International Railway and Motion Exhibition) grandly opened at the Russian Railway Museum in St. Petersburg. PRO//Motion Expo is currently the largest railway and transportation exhibition in Russia and the Commonwealth of Independent States (CIS), attracting extensive participation from railway companies from CIS countries and around the world. Over the four-day exhibition, exhibitors showcased cutting-edge tec...

-

2025 Russian International Railway and Rail Transit Exhibition: SinoMac invites you to join the industry feast

From August 28 to 31, 2025, the highly anticipated biennial Russian International Railway and Rail Transit Exhibition (PRO/Motion Expo) will be held in St. Petersburg. The exhibition is the largest and most professional railway and transportation exhibition in Eastern Europe and Central Asia. PRO/Motion Expo brings together industry elites, corporate representatives and professional visitors from all over the world to witness the latest development achievements and cutting-edge trends in the ...

-

About Motor and Electric Drive Adaptation

The motor-drive adaptation process refers to the process of matching the motor with the electric drive system. In actual applications, the motor and the electric drive may have different characteristics, such as voltage, power, speed range, etc. Therefore, in order to achieve optimal performance, efficiency and stability, they need to be properly matched and configured.The adaptation process usually includes the following steps: Specification analysis Evaluate the technical specifications of ...

-

Brief Analysis of Axle Failure

When judging the power performance of a vehicle, the first thing to look at is the engine, gearbox and axle, which are often called the "three major parts". It is these three parts that together make up the power chain of the truck. To solve the problem of axles, you must first understand what axles are. The explanation given by Baidu Encyclopedia is: "Axles are also called axles. They are connected to the frame through suspension, and wheels are installed at both ends. They are mainly used t...

-

USA | Construction – A USA Company’s Feedback

EMAC company till now, and EMAC provides us a very good support, no matter pre-sales support or after-sales support. They have deep network of power system manufacturers in China, and ensuring them the strong ability of giving multiple brands options, we are happy to be partner of EMAC, that able to provide us one-stop power system solution from China, and they always can give us best value for money solution based on our requirement...

Global Activity

Attending a Global Maritime Extravaganza, SinoMac will be showcasing at Marintec China 2025

Marintec China 2025, hailed as a "global trendsetter for the maritime industry," will be held from December 2nd to 5th, 2025, at the Shanghai New International Expo Centre. The theme of this year's exhibition is "Innovation and Cooperation for Sustainable Development of the Maritime Industry," and the theme of the High-Level Maritime Forum is "Intelligent Navigation, Green Coexistence, Integration, and Innovation," reflecting expectations for the industry's future.

Review SAUDI RAIL 2025 :SinoMac Exhibition Highlights

SinoMac successfully participated in SAUDI RAIL 2025, the annual industry event held in Riyadh, Saudi Arabia, from October 19th to 20th, 2025. At the exhibition, SinoMac showcased its strong capabilities in railway technology, innovative solutions, and full lifecycle services, and engaged in in-depth exchanges with industry partners, customers, and experts from around the world to jointly explore future opportunities for rail transit development in the Middle East.

Deeply Cultivate the International Market, Empowering the Future of Rail ——Focus [PRO//Motion Expo 2025]: SinoMac Exhibition Highlights Review

From August 28 to 31, 2025, the highly anticipated PRO//Motion Expo 2025 (Russian International Railway and Motion Exhibition) grandly opened at the Russian Railway Museum in St. Petersburg. PRO//Motion Expo is currently the largest railway and transportation exhibition in Russia and the Commonwealth of Independent States (CIS), attracting extensive participation from railway companies from CIS countries and around the world. Over the four-day exhibition, exhibitors showcased cutting-edge technologies and innovative achievements in the railway transportation industry.

2025 Russian International Railway and Rail Transit Exhibition: SinoMac invites you to join the industry feast

From August 28 to 31, 2025, the highly anticipated biennial Russian International Railway and Rail Transit Exhibition (PRO/Motion Expo) will be held in St. Petersburg. The exhibition is the largest and most professional railway and transportation exhibition in Eastern Europe and Central Asia. PRO/Motion Expo brings together industry elites, corporate representatives and professional visitors from all over the world to witness the latest development achievements and cutting-edge trends in the railway and rail transit industry. Here, many internationally renowned companies will showcase their latest technologies, products and solutions, covering railway infrastructure construction, train manufacturing, communication and signal systems, intelligent transportation and other fields. From advanced train design and manufacturing technology to efficient railway operation and management solutions; from innovative rail material research and development to intelligent railway communication and control systems, various cutting-edge technologies and innovative achievements will be presented one by one, bringing a wonderful industry feast to the participants.

Focus on marine industry event, start a new chapter of marine development together–SinoMac Group Limited to exhibit at Marine & Offshore Vietnam 2025

Against the backdrop of the booming development of the global shipping and maritime industry, Vietnam International Maritime Expo 2025 (Marine & Offshore Vietnam) will be held in Ho Chi Minh City, Vietnam from 19th to 21st November. As one of the most influential maritime events in Southeast Asia, this exhibition brings together top enterprises and innovations in the fields of global shipbuilding, offshore engineering, port equipment, new energy ship technology, etc., and provides an international platform for industry colleagues to exchange and co-operate and explore the market.

SinoMac Group Limited made its debut at the 2025 Indonesia International Construction Machinery, Mining and Concrete Exhibition

The International Exhibition of Engineering Machinery, Mining, and Concrete (Mining Indonesia) will be held in Jakarta, Indonesia, from September 17 to 20, 2025. As one of the most influential mining exhibitions in Southeast Asia, Mining Indonesia provides a professional platform for enterprises, experts, and practitioners in the global mining sector to showcase cutting-edge technologies, exchange industry insights, and explore collaborative opportunities.

SinoMac actively participated in the International Railway and Rail Transit Exhibition in Berlin, Germany, to explore the new future of the industry

From September 22 to 25, 2026, the highly anticipated biennial Berlin International Railway and Rail Transit Exhibition (InnoTrans Berlin) opened grandly in Berlin, Germany. As the largest and most influential event in the global railway and rail transit field, InnoTrans Berlin brings together industry elites, corporate representatives and professional visitors from all over the world to witness the latest development achievements and cutting-edge trends in the railway and rail transit industry. The exhibition covers a number of key areas such as bridges and tunnels, public transportation, and comprehensively displays innovative technologies, advanced equipment and comprehensive solutions in the railway and rail transit industry. From infrastructure construction to operation management, from vehicle manufacturing to intelligent system applications, the exhibition content is rich and diverse, providing participants inside and outside the industry with an excellent platform for a comprehensive understanding of industry dynamics, exchanges and cooperation.

SinoMac makes a brilliant appearance at Eurasia Rail Turkey 2025

From June 18 to 20, 2025, the highly anticipated 2025 Turkey Railway, Rolling Stock and Logistics Exhibition (Eurasia Rail Turkey) opened grandly at the Istanbul Expo Center (IFM). As one of the most influential industry events in the railway and rail transit fields in the Middle East, Africa and Europe, this exhibition attracted many outstanding companies from the global rail transit, rolling stock and logistics technology fields to participate in the exhibition. During the three-day exhibition, the exhibitors concentrated on displaying the industry's cutting-edge technologies and innovative achievements, building an efficient technical exchange and business cooperation platform for international professionals, and providing an important opportunity to promote the development of the global rail transit industry.

SinoMac Makes a Grand Appearance at the 2025 Kazakhstan International Mining, Exploration and Coal Processing Exhibition

The 2025 Kazakhstan International Mining, Exploration and Coal Processing Exhibition (Mining Week) is set to take place grandly in Karaganda, Kazakhstan, from June 24 to 26. As one of the most influential mining exhibitions in Central Asia, Mining Week provides a professional platform for enterprises, experts, and practitioners in the global mining sector to highlight innovative technologies, exchange industry experiences, and explore cooperation opportunities.

Focus on the Railway and Rail Transit Expo, and Join Forces to Promote the Development of the Rail Transit Industry—— SinoMac is Set to Appear at the 2025 Turkey Railway and Rail Transit Exhibition

Against the backdrop of the vigorous development of the rail transit industry, the 2025 Turkey Railway and Rail Transit Exhibition will open its curtains in Istanbul, Turkey from June 18 to 20. As a much - anticipated industry event, this exhibition offers a broad platform for global rail transit companies to showcase their innovative achievements and expand market opportunities, covering various aspects of the rail transit field, including railways, subways, light rails, trams, locomotives, vehicles, signaling and communication systems, and maintenance and repair equipment.