Today we will mainly talk about the definition, development history, types, models, parameters, disassembly diagrams and names of various parts of railway freight car bogies.

Railway freight car bogies, also known as railway freight car running gear, are key components of railway freight cars. They play an important role in bearing the load from the car body and the track, guiding the vehicle along the rails, and alleviating the force of movement.

After more than 70 years of development, China Railway’s freight car bogies have achieved remarkable achievements in heavy-load and speed-increasing technologies. The axle weight of general-purpose freight cars has increased from 21 tons to 25 and 27 tons, and that of special-purpose freight cars to 30 tons. The operating speed of these cars has also increased from 50-60 km/h to 100-120 km/h.

Since the founding of the People’s Republic of China, my country’s railway freight car bogies have undergone three major development phases. The first phase, from 1949 to 1963, saw the coexistence of various types of bogies, primarily copied from other models. The second phase, from 1964 to 1997, saw the production and operation of independently designed and manufactured bogies, with the Zhuan-8A bogie as the primary model. The third phase, from 1998 to the present, has witnessed the innovative development of high-speed, heavy-load bogies. During these three phases, four major technological upgrades have been achieved.

The first technological upgrade, from the founding of the People’s Republic of China to the 1970s, gradually eliminated various miscellaneous bogies with poor performance and low axle loads. The simpler, higher-performing Zhuan-8A bogie became the primary bogie for freight cars, increasing freight car operating speeds from 50-60 km/h to 70-80 km/h.

The third technical upgrade was from 2003 to 2011. New freight cars gradually stopped being equipped with 21t axle-load bogies, and 70t-class general-purpose freight cars and 80t-class special-purpose freight cars fully adopted the Zhuan K6 and Zhuan K5 speed-raising heavy-duty bogies, increasing the axle weight of my country’s railway freight cars from 21t to 23-25t and the speed to 100-120km/h.

The second technological upgrade was from the 1990s to 2003. The side frame cross-support technology was used to speed up the Zhuan 8A bogie. The production of Zhuan 8A bogies was stopped and the Zhuan K2 side frame cross-support bogies were fully adopted to replace the Zhuan 8A bogies in freight cars, increasing the operating speed of freight cars from 70~80 km/h to 120 km/h.

The fourth technological upgrade began in 2011, when my country began to develop and apply 27t axle-load DZ1, DZ2, and DZ3 bogies and 30t axle-load DZ4 and DZ5 bogies. The maximum operating speed meets the operational requirement of 100 km/h. The axle weight, traction weight, and annual transport volume of my country’s railway freight cars have reached international heavy-load standards.

1. 21t axle load bogie

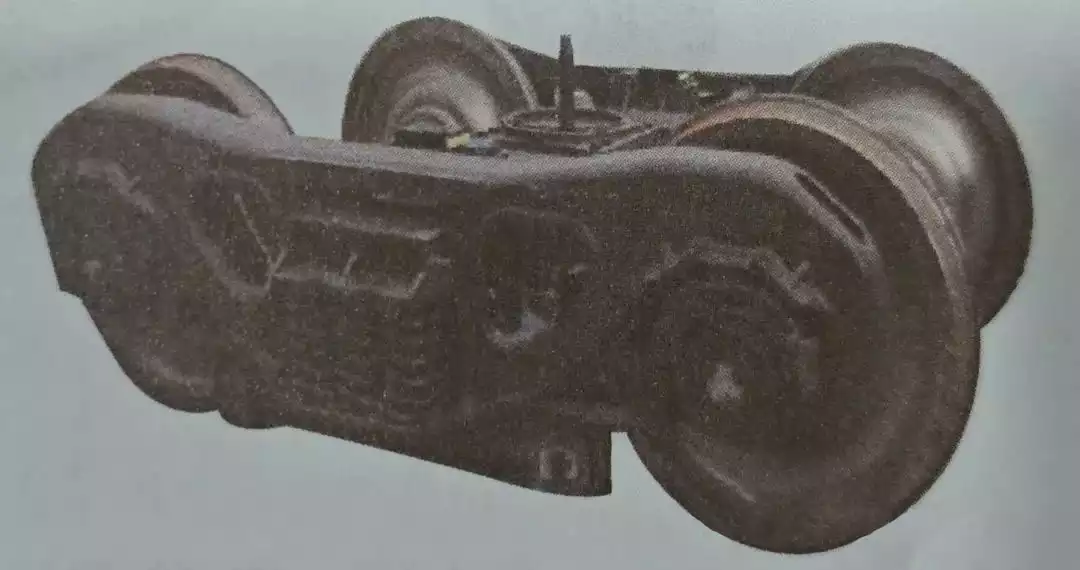

my country’s 21t axle load bogies primarily include the Zhuan 8 series, Zhuan K2, Zhuan K3, and Zhuan K4 bogies. The Zhuan 8 series, further comprising the Zhuan 8A, Zhuan 8G (Zhuan 8AG), and Zhuan 8B (Zhuan 8AB) bogies, was once the primary bogie type for my country’s 21t axle load railway freight cars, but was later replaced by the Zhuan K2 bogie.

1. Zhuan K2 Bogie

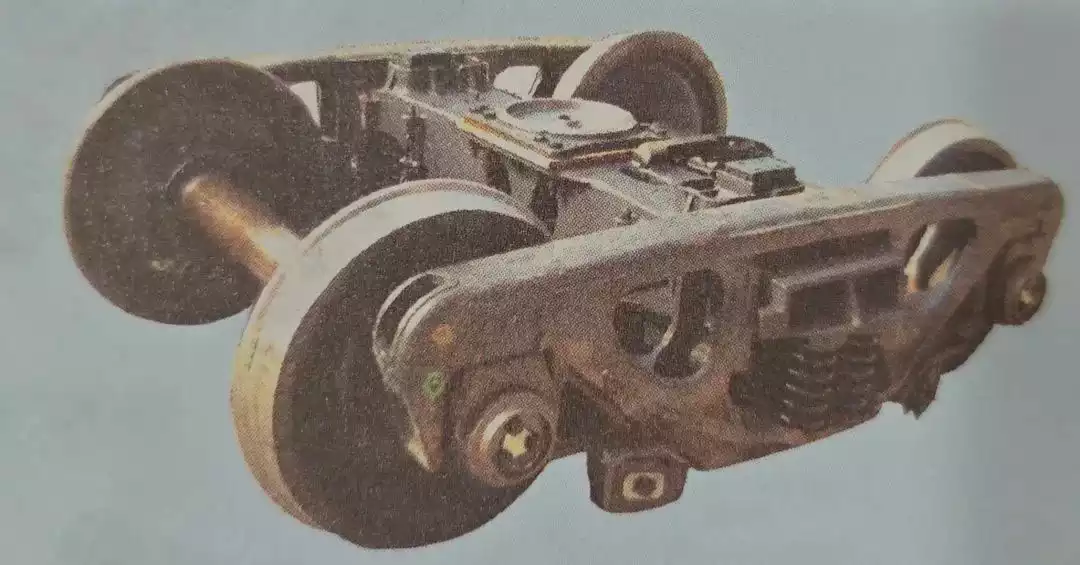

The Zhuan K2 bogie features a lower cross-bracing device to enhance bogie anti-slip rigidity, suppress vehicle snaking and instability, and improve derailment safety for empty wagons. This improves the dynamic performance of traditional three-piece bogies and meets my country’s railway freight car speed requirements of 120 km/h. The Zhuan K2 bogie is primarily designed for use in my country’s 21-ton axle-load open wagons, covered wagons, flat wagons, tank wagons, hopper wagons, and container wagons.

3. Zhuan K4 Bogie

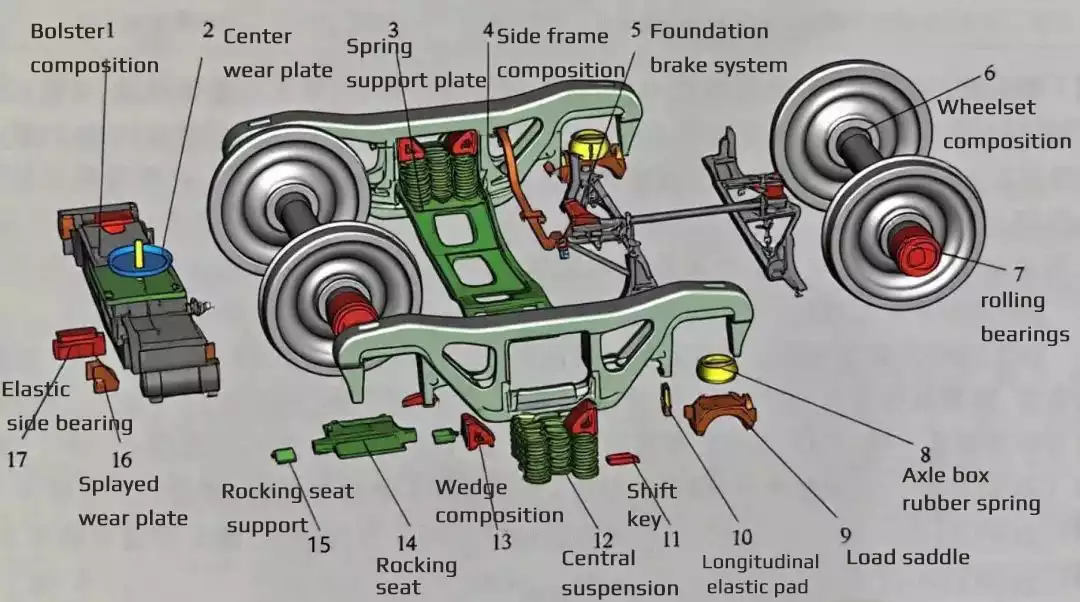

The Zhuan K4 bogie incorporates new technologies such as two-stage springs, nylon core wear plates, constant-contact elastic side bearings, combined cams, and combined brake beams. It employs a rocker-sway mechanism similar to that used on passenger car bogies, resulting in a two-stage lateral stiffness characteristic. This increases the vehicle’s lateral flexibility, improves lateral dynamics, reduces wheel-rail wear, and enhances vehicle ride quality.

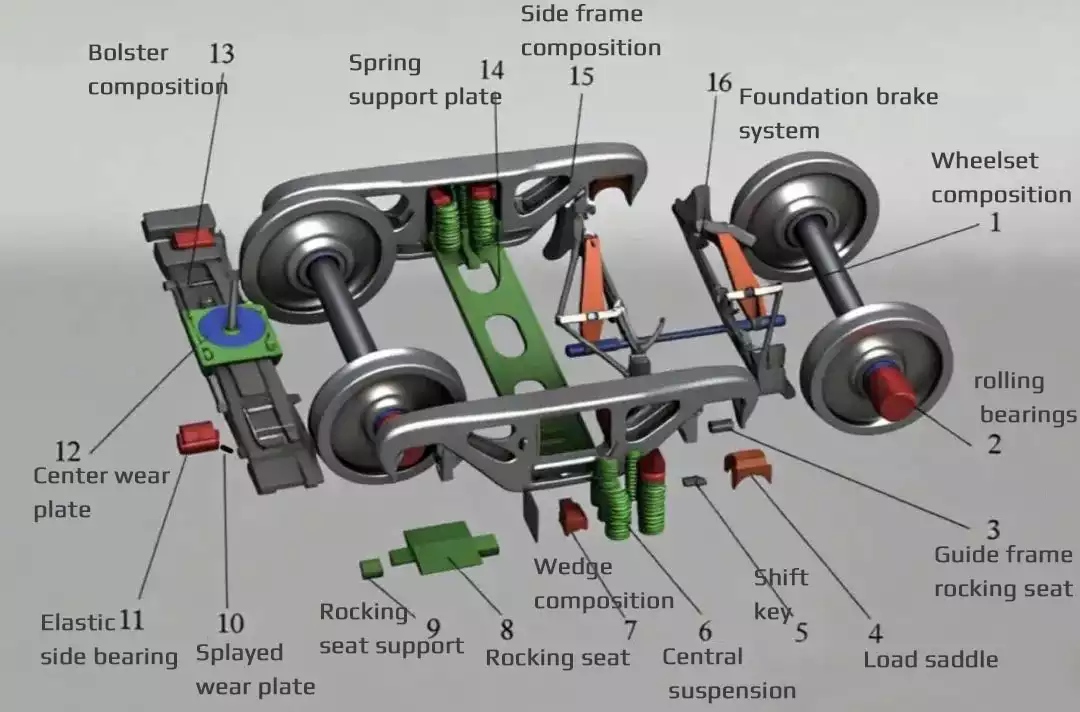

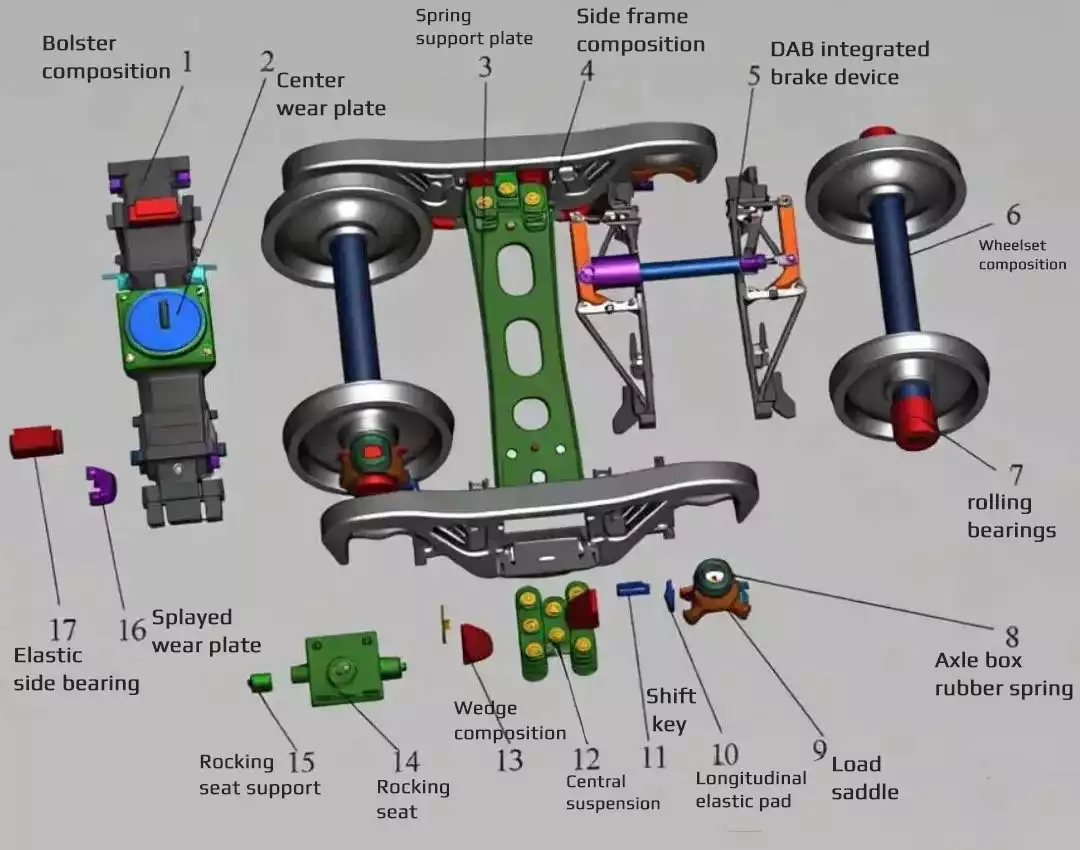

The Zhuan K4 bogie structure builds on the traditional three-piece bogie by adding a spring support plate, improving the bogie’s anti-slip stiffness and vehicle lateral ride quality. It is installed on new models such as the C64H, NX17BH, and C70E(H). It primarily consists of a bolster, side frame, spring support plate, rocker seat, rocker seat support, load spring, vibration damping device, wheelset and bearings, foundation brake system, and constant-contact elastic side bearings.

2. Zhuan K3 Bogie

The Zhuan K3 bogie utilizes an integrally welded frame, axlebox spring primary suspension, constant contact elastic side bearings, and a spherical center plate. It features high anti-friction stiffness, a high critical speed, light unsprung mass, and minimal wheel-rail motion. It is primarily used on X1K express container flatcars.

Bogie Model | Zhuan K2 | Zhuan K3 | Zhuan K4 |

| Gauge (mm) | 1435 | 1435 | 1435 |

| Axle Load (t) | 21 | 21 | 21 |

| Dead Weight (t) | ≤4.2 | About 4.2 | ≤4.2 |

| Maximum Operating Speed (km/h) | 120 | 120 | 120 |

| Wheel Diameter (mm) | 840 | 840 | 840 |

| Fixed Wheelbase (mm) | 1750 | 1800 | 1750 |

| Distance between Journal Centers (mm) | 1956 | 1956 | 1956 |

| Distance between Side Bearings (mm) | 1520 | 1520 | 1520 |

| Diameter of Lower Center Plate (mm) | 355 | SR190 | 355 |

| Brake Ratio of Foundation Brake Device | 4 | 6.48 | 6 |

| Minimum Curve Radius Passed (m) | 100 | 100 | 100 |

| ——END—— | |||

2. 23t (25t) axle load bogie

2. Zhuan K6 Bogie

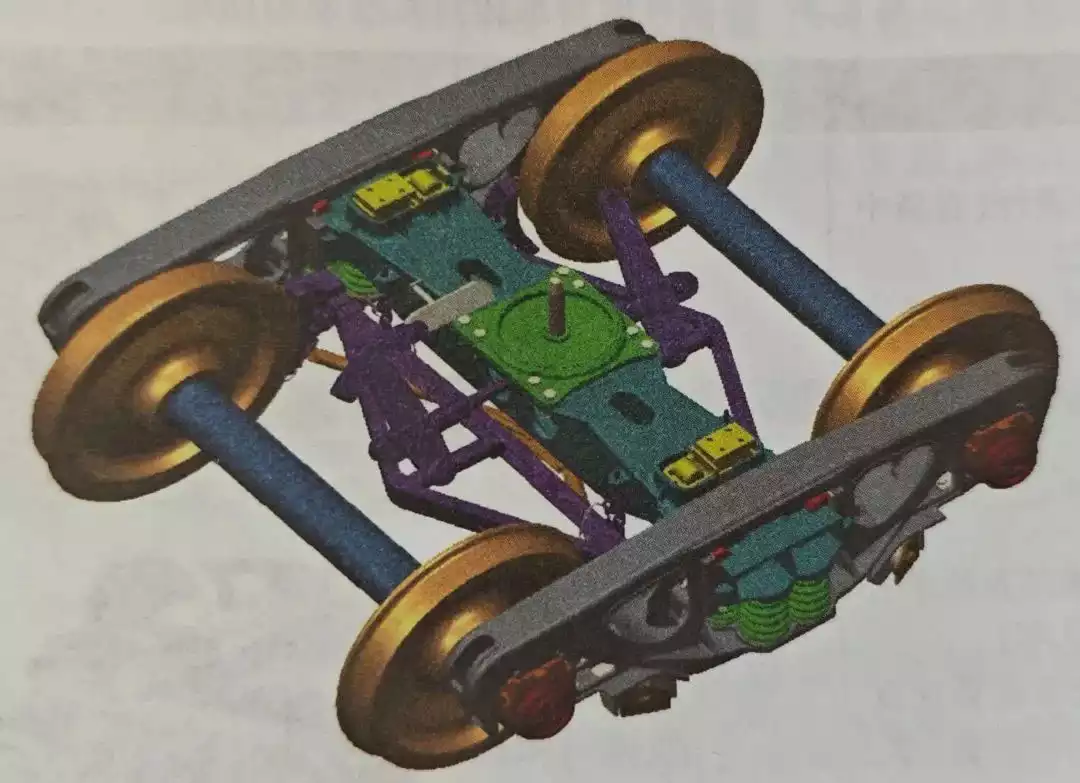

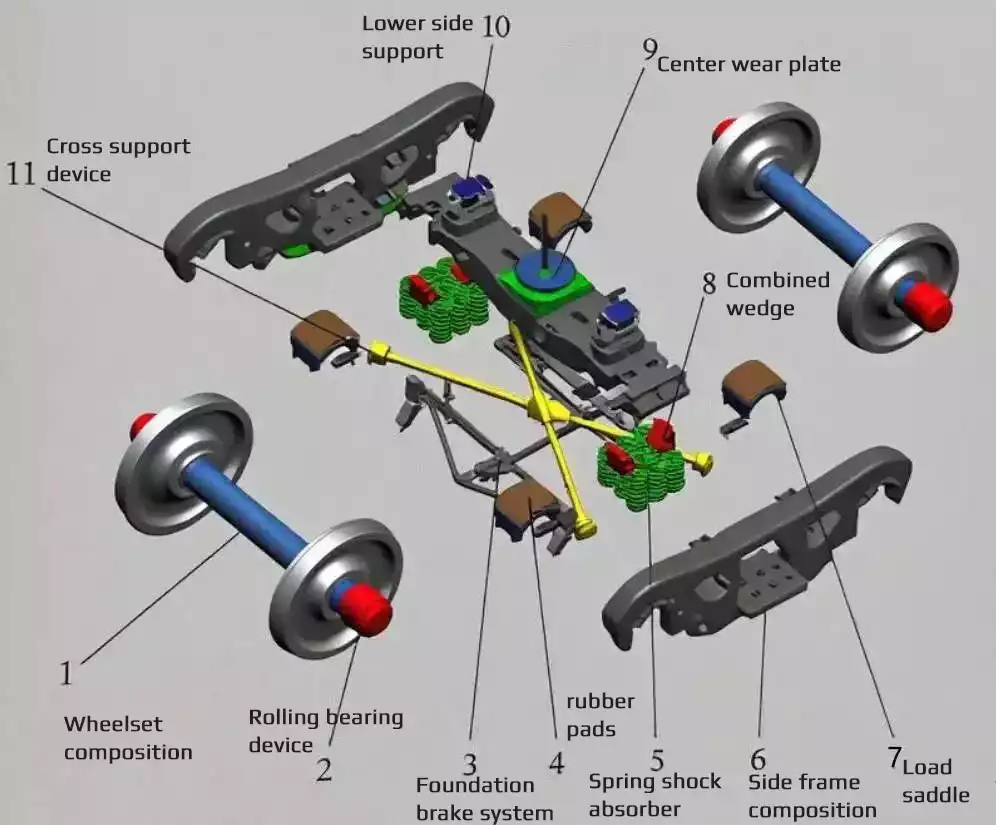

The Zhuan K6 bogie is an independently designed and developed model based on the Zhuan K2 bogie, featuring an additional primary axlebox elastic suspension. It utilizes new technologies such as primary axlebox elastic suspension, lower cross bracing, two-stage springs, nylon center plate wear plates, constant contact rubber elastic side bearings, combined cams, and a combined brake beam.

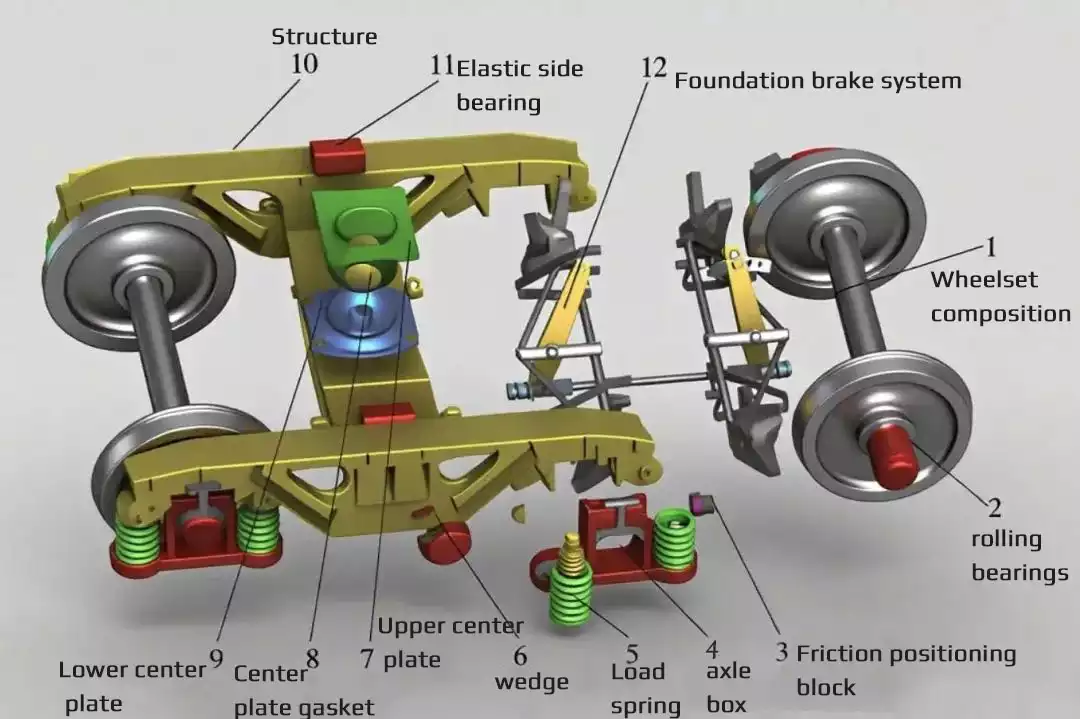

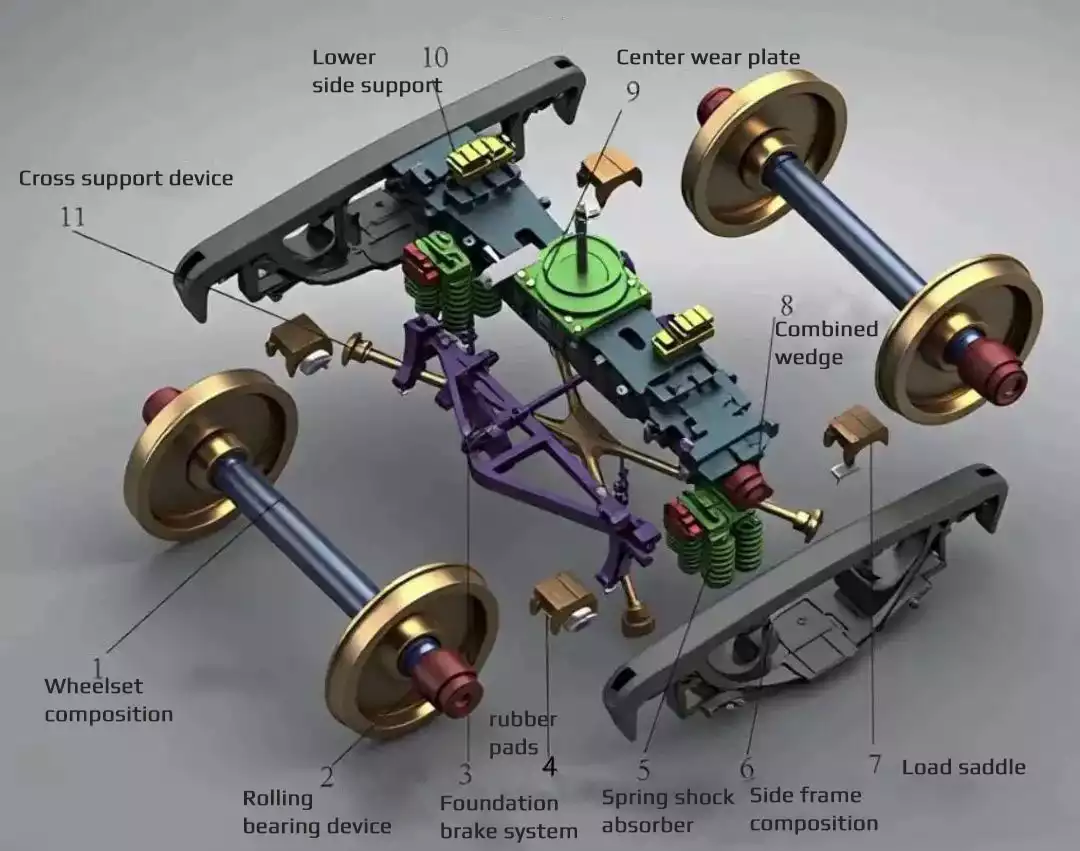

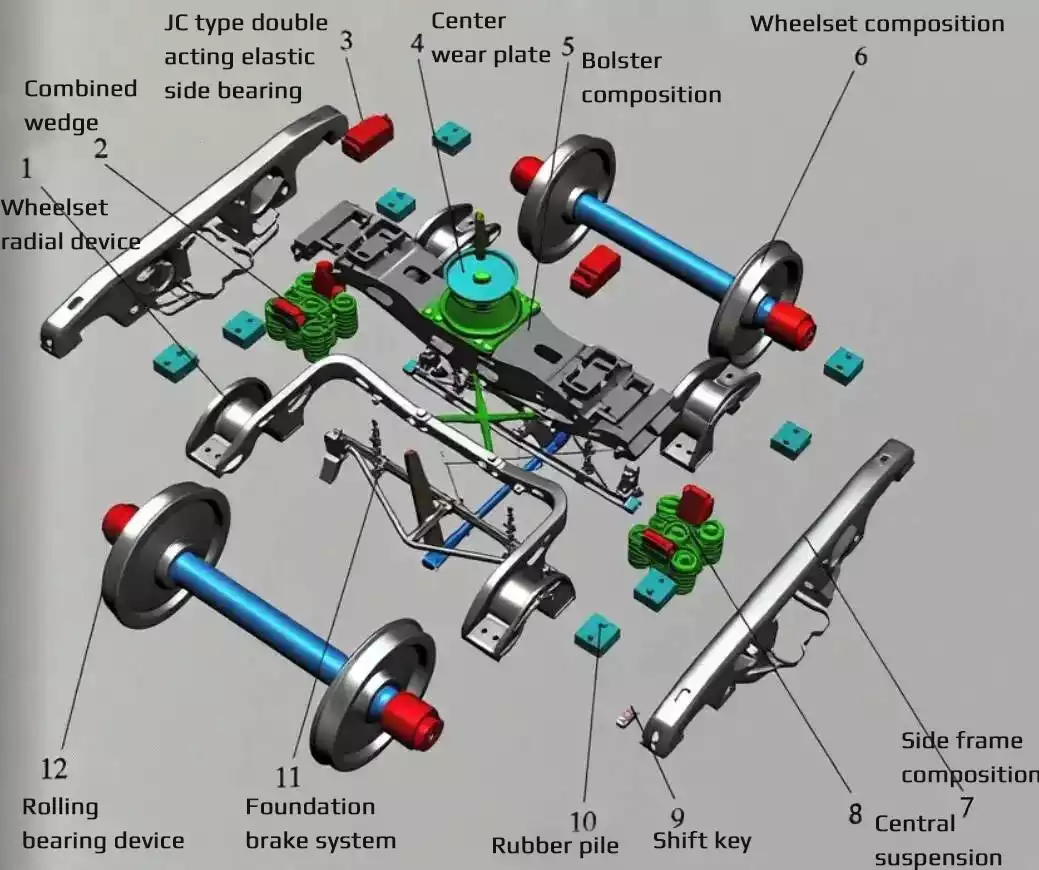

The Zhuan K6 bogie is a three-piece cast steel, lower cross-braced bogie, primarily consisting of wheelsets, sideframes, rubber pads, bolsters, foundation brakes, cross bracing, rolling bearings, double-acting elastic side bearings, and cams.

1. Zhuan K5 Bogie

The Zhuan K5 bogie is independently designed and developed based on the Zhuan K4 bogie. It incorporates new technologies, including a sideframe swing mechanism, two-stage springs, a nylon center plate wear plate, constant contact elastic side bearings, a combined cam, and a combined brake beam. It features an E-axle axle, a wheelbase increased to 1800mm, a concave spring support instead of a flat plate, two sets of load-bearing springs at one end of the bolster, a 375mm lower center plate diameter, and enlarged bolster and sideframe cross-sections. It is primarily used on vehicles such as the C70H, P70H, C80H, and C80BH.

3. Zhuan K7 Bogie

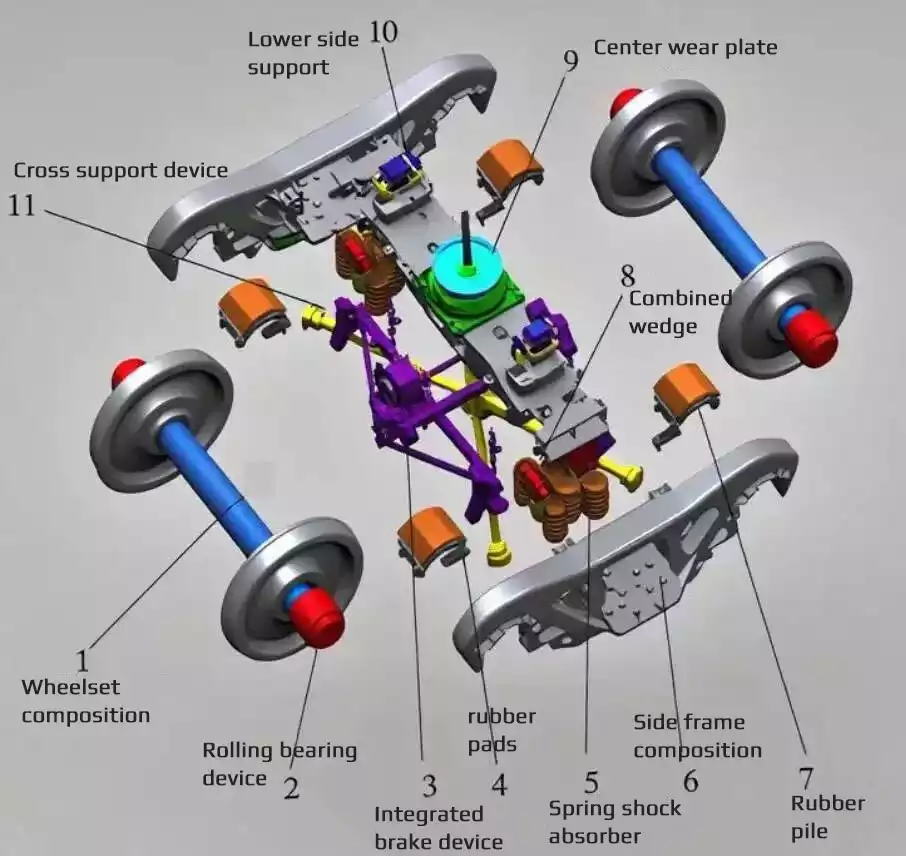

The Zhuan K7 bogie is a 25t axle-load radial bogie developed based on my country’s track conditions and manufacturing, maintenance, and operational requirements. It incorporates a series of new technologies, including wheelset radial positioning, low-rigidity axlebox rubber pads, two-stage springs, double-acting elastic side bearings, and combined cams. By connecting the front and rear wheelsets with a wheelset radial device, kinematic coupling is achieved. This not only increases the bogie’s shear stiffness and enhances operational stability, but its reduced bending stiffness also reduces wheelset sway, improving cornering performance and reducing wheel-rail wear. Furthermore, the sub-frame radial bogie distributes wheel-rail lateral forces more evenly across each wheelset, reducing peak wheel-rail lateral forces and achieving low dynamic forces.

The Zhuan K7 bogie primarily consists of wheelsets, sideframes, bolsters, rubber pads, foundation brakes, rolling bearings, elastic side bearings, wheelset radial devices, and central suspension. The Zhuan K7 bogie is primarily used on C80B open-top wagons.

Bogie Model | Zhuan K5 | Zhuan K6 | Zhuan K7 |

| Gauge (mm) | 1435 | 1435 | 1435 |

| Axle Load (t) | 25 | 25 | 25 |

| Dead Weight (t) | ≤4.7 | 4.68 | About 4.7 |

| Maximum Operating Speed (km/h) | 120 | 120 | 120 |

| Wheel Diameter (mm) | 840 | 840 | 840 |

| Fixed Wheelbase (mm) | 1800 | 1830 | 1800 |

| Distance between Journal Centers (mm) | 1981 | 1981 | 1981 |

| Distance between Side Bearings (mm) | 1520 | 1520 | 1520 |

| Diameter of Lower Center Plate (mm) | 375 | 375 | 375 |

| Brake Ratio of Foundation Brake Device | 4 | 4 | 6 |

| Minimum Curve Radius Passed (m) | 145 | 145 | 145 |

| ——END—— | |||

3. 27t axle load bogie

1. DZ1 Bogie

The DZ1 bogie is a high-axle-load, low-power cross-bracing bogie independently developed in my country. It utilizes new technologies, including a lower cross brace, two-stage springs, nylon core wear plates, constant-contact rubber elastic side bearings, combined cams, combined brake beams, a weld-free structure, and integral core casting of the bolster and side frames.

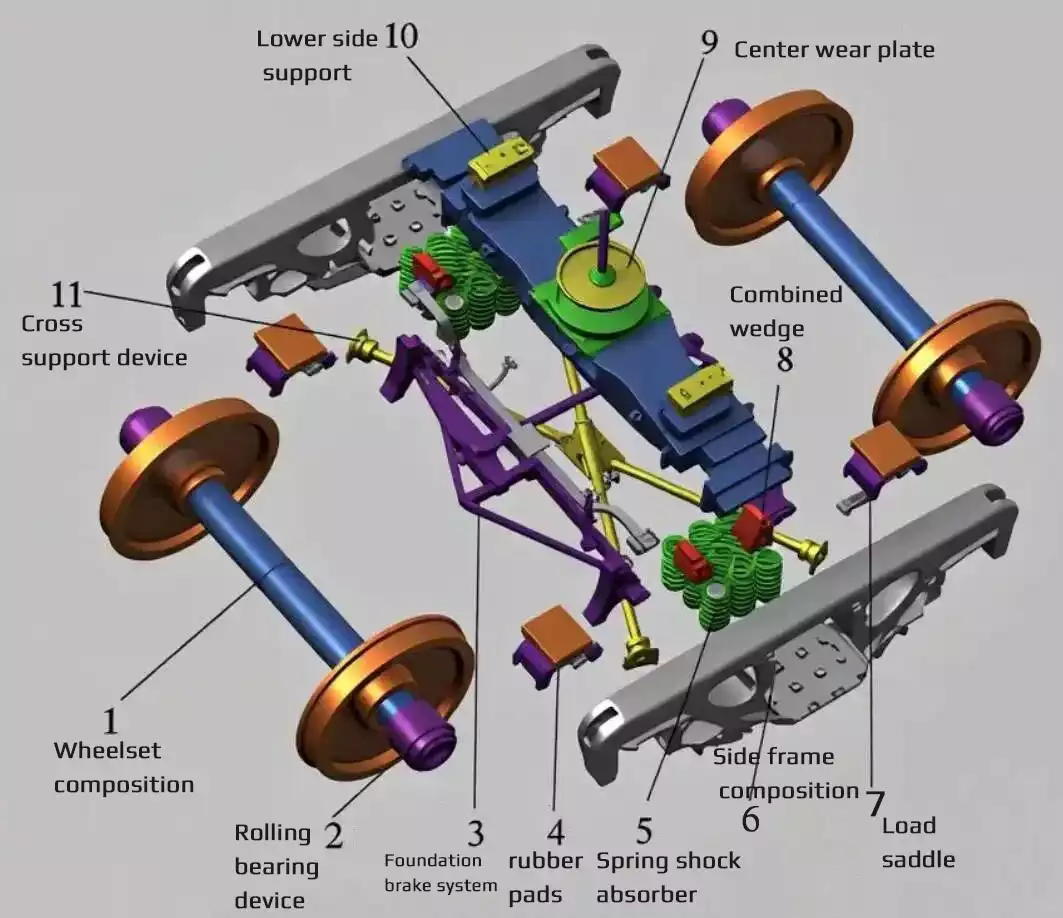

The DZ1 bogie is a three-piece cast steel cross-bracing bogie, primarily consisting of wheelsets, rolling bearings, side frames, bolsters, brakes, spring dampers, elastic side bearings, axlebox rubber pads, and cross bracing. The DZ1 bogie is primarily used on 27t axle-load general-purpose freight cars, such as the C80E, P80, and GQ80.

3. DZ3 Bogie

The DZ3 bogie is a high-axle-load, sub-frame radial bogie developed and designed through independent innovation based on the operational experience of the K7 bogie and related technical research results, with the goal of adapting it to heavy-load transportation on existing lines.

The DZ3 sub-frame bogie is a three-piece cast steel freight car bogie, primarily consisting of a wheelset, rolling bearings, bolster, sideframe, elastic side bearings, brake assembly, spring damper, wheelset radial assembly, and rubber pads. The DZ3 bogie is primarily used on C80EF open wagons.

2. DZ2 Bogie

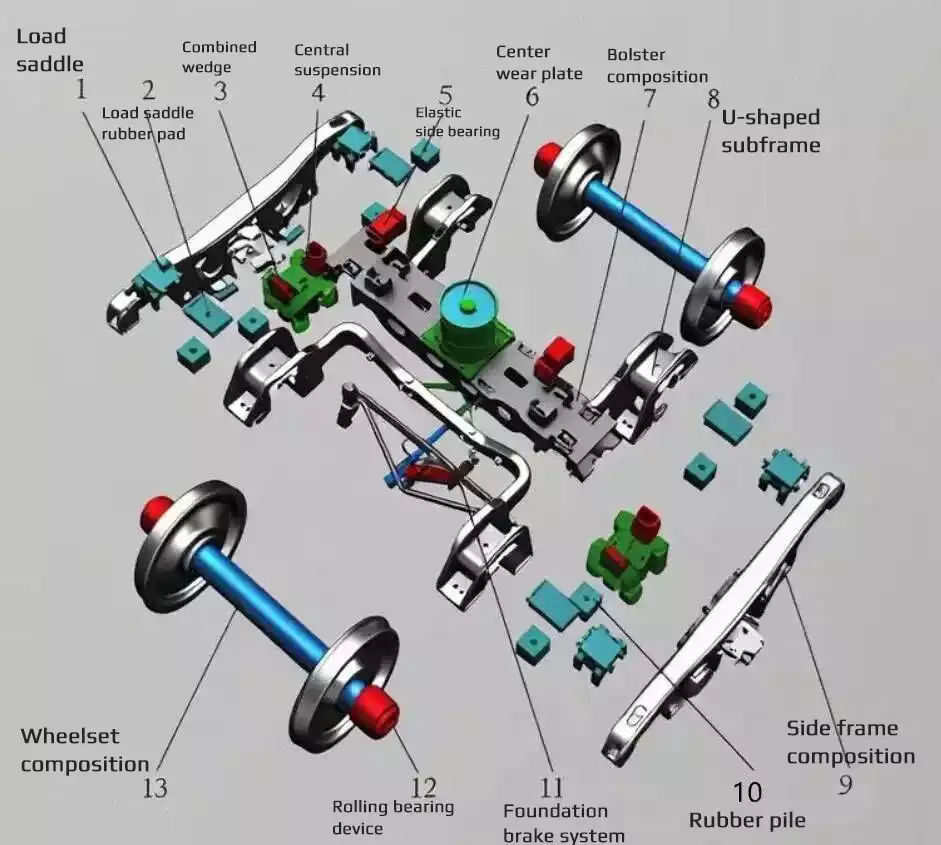

The DZ2 bogie is a self-developed, high-axle-load, low-power swing-type freight car bogie. It incorporates new technologies, including a sideframe swing mechanism, primary axlebox rubber elastic suspension, two-stage springs, nylon core wear plates, constant-contact elastic side bearings, combined cams, combined brake beams, embedded splayed wear plates, wear-resistant bushings, a weld-free structure, and integral core casting of the bolster and sideframes.

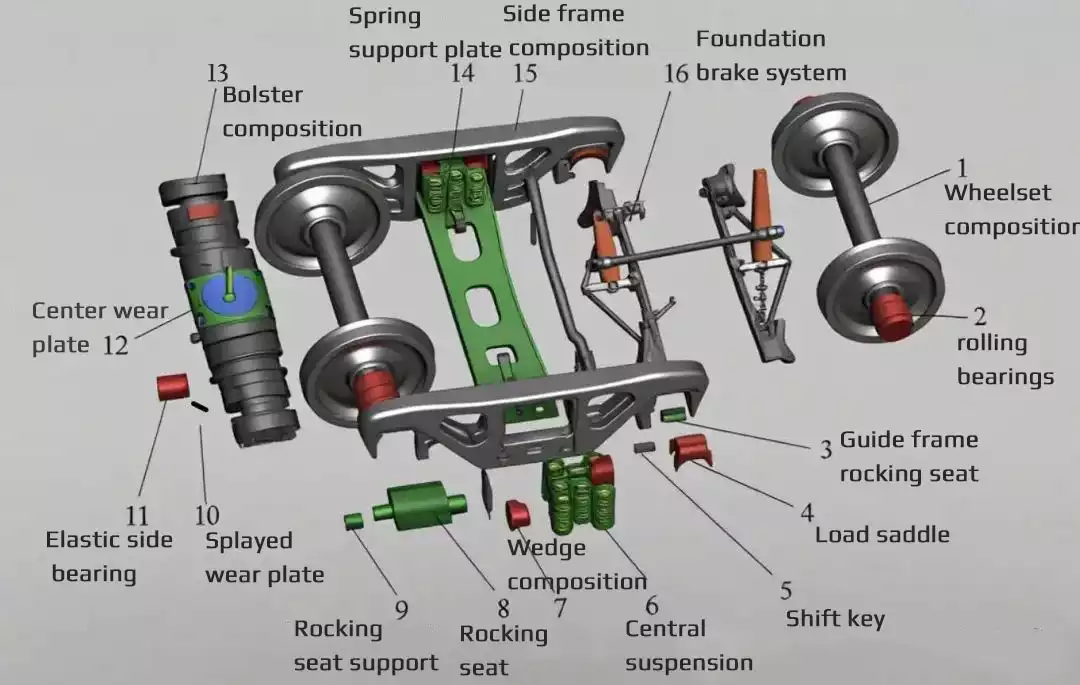

The DZ2 bogie is a three-piece cast steel freight car bogie consisting primarily of wheelsets, rolling bearings, sideframes, bolsters, brakes, spring dampers, elastic side bearings, axlebox suspension, rocker seats, and spring supports. The DZ2 bogie is primarily used on C80EH open wagons.

Bogie Model | DZ1 | DZ2 | DZ3 |

| Gauge (mm) | 1435 | 1435 | 1435 |

| Axle Load (t) | 27 | 27 | 27 |

| Dead Weight (t) | 5.15 | 5.2 | 5.44 |

| Maximum Operating Speed (km/h) | 100 | 100 | 100 |

| Wheel Diameter (mm) | 915 | 915 | 915 |

| Fixed Wheelbase (mm) | 1860 | 1860 | 1860 |

| Distance between Journal Centers (mm) | 2006.6 | 2006.6 | 2006.6 |

| Distance between Side Bearings (mm) | 1520 | 1520 | 1520 |

| Diameter of Lower Center Plate (mm) | 375 | 375 | 375 |

| Brake Ratio of Foundation Brake Device | 4 | 4 | 6 |

| Minimum Curve Radius Passed (m) | 145 | 145 | 145 |

| ——END—— | |||

4. 30t axle load bogie

2. DZ5 Bogie

The DZ5 bogie is a self-developed, high-axle-load, low-power swing bogie. It incorporates new technologies, including a sideframe swing mechanism, primary axlebox rubber suspension, two-stage springs, nylon core wear plates, constant-contact rubber side bearings, combined cams, unitized brake cylinders, embedded splayed wear plates, a weld-free construction, bolsters, and integrally cast sideframe cores.

The DZ5 bogie structure is essentially the same as the DZ2 bogie. The crossbeam support is integrally cast with the sideframes. The DZ5 bogie is primarily used for 30t axle-load special-purpose freight cars, such as the C96H and KM98AH.

1. DZ4 Bogie

The DZ4 bogie is a self-developed, high-axle-load, cross-braced bogie. It utilizes new technologies, including a two-stage spring for the lower cross support, a nylon core wear plate, constant-contact elastic side bearings, a combined cam, a combined brake beam, a weld-free structure, and integrally cast cores for the bolster and side frames.

The DZ4 bogie’s main structure is essentially the same as the DZ1 bogie. The crossbeam bracket and support bracket are integrally cast with the side frames. The DZ4 bogie is primarily used for 30t axle-load special-purpose freight cars, such as the C96 and KM98.

Bogie Model | DZ4 | DZ5 |

| Gauge (mm) | 1435 | 1435 |

| Axle Load (t) | 30 | 30 |

| Dead Weight (t) | ≤5.4 | ≤5.4 |

| Maximum Operating Speed (km/h) | 100 | 100 |

| Wheel Diameter (mm) | 915 | 915 |

| Fixed Wheelbase (mm) | 1860 | 1860 |

| Distance between Journal Centers (mm) | 2006.6 | 2006.6 |

| Distance between Side Bearings (mm) | 1520 | 1520 |

| Diameter of Lower Center Plate (mm) | 419 | 419 |

| Inner Diameter of Center Plate Wear Plate (mm) | 405 | 405 |

| ——END—— | ||