Volt : 540 VDC

Rated / Prak Power : 20 / 40 kw

Rated / Peak Torque : 150 / 300 Nm

Rated / Peak RPM : 1273 / 2400 RPM

Drive Motor

As the “heart” of new energy vehicles, the drive motor is a core device that converts electrical energy into mechanical energy, providing powerful driving force for vehicle movement. Based on the principle of electromagnetic induction, it generates a rotating magnetic field when the stator winding is energized, interacting with the rotor to drive the rotor to rotate at high speed, thus driving the wheels. Compared with traditional internal combustion engines, the drive motor has a significant advantage of rapid response, capable of reaching maximum torque instantaneously, enabling vehicles to start quickly and accelerate rapidly. Its high – efficiency energy conversion rate exceeds 90%, far surpassing that of traditional engines. This reduces energy loss and effectively extends the vehicle’s driving range. In terms of technological innovation, permanent magnet synchronous motors have become the mainstream due to their characteristics of high power density, high efficiency, and small size. The application of rare – earth permanent magnet materials further enhances the magnetic performance of the motors. The adoption of flat – wire winding technology increases the effective cross – sectional area of the wires, reduces resistance losses, and improves heat dissipation performance, significantly increasing the motor’s power density. In addition, the drive motor has a highly integrated feature, which can be deeply integrated with components such as reducers and controllers, simplifying the power system structure and reducing vehicle weight. With its excellent performance and advanced technology, the drive motor is widely used in new energy passenger vehicles, commercial vehicles, and special – purpose vehicles, injecting strong impetus into the global green transportation revolution.

Advantages of Drive Motor

- Low total cost of ownership: Although the initial procurement cost of the drive motor may be relatively high, during the entire usage cycle, it is powered by electricity, resulting in significantly lower energy costs compared to fuel engines. Coupled with reduced maintenance expenses due to low maintenance requirements and less frequent replacement due to its long lifespan, the overall usage cost is much lower than that of traditional power equipment, demonstrating strong cost – effectiveness in long – term operation.

- Intelligent connectivity and self – diagnosis: Modern drive motors can be integrated with various sensors and communication modules, featuring intelligent connectivity functions. They can interact with the vehicle’s central control system in real – time to monitor the motor status and issue fault warnings. The built – in self – diagnosis system can quickly locate fault points, facilitating timely troubleshooting and repair by maintenance personnel, thereby improving the overall reliability and operation and maintenance efficiency of the vehicle.

As the power core of new energy equipment, the TZ180 drive motor shoulders the key mission of converting electrical energy into mechanical energy and providing driving force for vehicles, mechanical devices, etc. Its operation is based on the principle of electromagnetic induction. The CRRC Zhuzhou 1435 series dual rail sightseeing car inherits the technological DNA of CRRC high-speed rail and is designed for in-depth sightseeing in scenic areas. The innovative double-decker structure features a panoramic window on the first floor for comfortable all-weather sightseeing and an open-top layout on the second floor for a 360° immersive natural experience. CHSR's CHSR™ CC750 air-cooled converter is a highly integrated traction and auxiliary "two-in-one" core equipment. It condenses key power conversion functions into a single compact enclosure, providing robust and stable power for intercity trains through standardized modular design, intelligent air cooling (IP65 protection), and mature and reliable components. CRRC Braking Systems Co., Ltd.'s disc brake calipers use hydraulic or pneumatic-hydraulic conversion drive technology.They integrate automatic gap adjustment, modular caliper body, and three-point floating suspension design to ensure precise contact between brake pads and discs. RailMac provides railway solutions, focusing on one-stop Lince/Huanji wiper services (R&D, production, maintenance) plus rail air conditioning. It offers diverse wipers (DC110V/74V/24V, pneumatic) and developed China’s first IP-owned CRH3 EMU wiper, with products batch-loaded in CRH380/CR400BF/CR300BF. RunWell is a high-tech enterprise specializing in the fields of rail transit and military industry. Its car lift machine products integrate German drive technology (such as the Demag three-in-one modular system) with intelligent control, supporting heavy-duty conditions of over 150 tons. CRRC specializes in innovative environmental protection sanitation systems. Products like vacuum water - saving toilet modules and waterless ecological toilets, made in an orderly factory, are applied in railways, public facilities, and outdoor scenarios. Partnering with global leaders, RailMac offers superior railway equipment and solutions at competitive prices. It hit milestones like Thailand’s 2017 first local train, pioneered SEA new energy trains, and joined Russia’s high-speed rail project, boosting its railway industry presence.TZ180 Drive Motor

Tourist Train

Traction System

Bogie and Braking System

Track Body Components

Maintenance Equipment

Railway Components

RailMac

Find Drive Motor by Series

This is the list of all series of Drive Motor.

Click here to find Drive Motor by type.

| 25-70 kW | ||||||||

| 25-70 kW | ||||||||

| 75 kW | ||||||||

| 60-100 kW | ||||||||

| 120-215 kW | ||||||||

| 120-215 kW | ||||||||

| 45-100 kW | ||||||||

Engine Model Power/kW | 0 | 50 | 100 | 150 | 200 | 250 | 300 | 350 |

| Drive Motor Catalogue | ||||||||

Volt : 320 VDC Volt : 618 VDC Volt : 350 VDC TZ180XS009-II

Rated / Prak Power : 30 / 60 kw

Rated / Peak Torque : 100 / 225 Nm

Rated / Peak RPM : 2865 / 9000 RPM TZ180XS009-I

Rated / Prak Power : 60 / 125 kw

Rated / Peak Torque : 120 / 200 Nm

Rated / Peak RPM : 4775 / 7500 RPM TZ180XS014E

Rated / Prak Power : 40 / 75 kw

Rated / Peak Torque : 48 / 130 Nm

Rated / Peak RPM : 8100 / 12000 RPM

Volt : 540 VDC Volt : 540 VDC Volt : 320 VDC Volt : 540 VDC Volt : 350 VDC TZ220XS017A

Rated / Prak Power : 60 / 80 kw

Rated / Peak Torque : 360 / 560 Nm

Rated / Peak RPM : 1600 / 2400 RPM TZ220XS020A

Rated / Prak Power : 32.5 / 70 kw

Rated / Peak Torque : 225 / 450 Nm

Rated / Peak RPM : 2860 / 6500 RPM TZ220XS028A

Rated / Prak Power : 30 / 60 kw

Rated / Peak Torque : 100 / 225 Nm

Rated / Peak RPM : 8100 / 12000 RPM TZ220XS026A

Rated / Prak Power : 70 / 145 kw

Rated / Peak Torque : 150 / 330 Nm

Rated / Peak RPM : 4450 / 12000 RPM TZ220XS013A

Rated / Prak Power : 60 / 130 kw

Rated / Peak Torque : 140 / 32 Nm

Rated / Peak RPM : 4000 / 12000 RPM

Volt : 640 VDC TZ260XS002A

Rated / Prak Power : 90 / 165 kw

Rated / Peak Torque : 300 / 600 Nm

Rated / Peak RPM : 2860 / 10000 RPM

Volt : 540 VDC Volt : 360 VDC Volt : 540 VDC Volt : 540 VDC Volt : 540 VDC Volt : 540 VDC TZ290XS027A

Rated / Prak Power : 110 / 190 kw

Rated / Peak Torque : 450 / 900 Nm

Rated / Peak RPM : 2400 / 7500 RPM TZ290XS022B

Rated / Prak Power : 70 / 120 kw

Rated / Peak Torque : 445 / 1100 Nm

Rated / Peak RPM : 1500 / 4500 RPM TZ290XS024B

Rated / Prak Power : 70 / 120 kw

Rated / Peak Torque : 445 / 1100 Nm

Rated / Peak RPM : 1500 / 4500 RPM TZ290XS010

Rated / Prak Power : 80 / 150 kw

Rated / Peak Torque : 230 / 650 Nm

Rated / Peak RPM : 3320 / 10000 RPM TZ290XS036A

Rated / Prak Power : 70 / 150 kw

Rated / Peak Torque : 225 / 450 Nm

Rated / Peak RPM : 2971 / 10000 RPM TZ290XS017C

Rated / Prak Power : 77.5 / 150 kw

Rated / Peak Torque : 238 / 554 Nm

Rated / Peak RPM : 3118 / 7500 RPM

Volt : 600 VDC Volt : 600 VDC Volt : 540 VDC Volt : 540 VDC Volt : 500 VDC Volt : 540 VDC Volt : 540 VDC Volt : 5400 VDC Volt : 450 VDC Volt : 540 VDC TZ380XS017J

Rated / Prak Power : 250 / 410 kw

Rated / Peak Torque : 1750 / 2800 Nm

Rated / Peak RPM : 1364 / 3500 RPM TZ380XS017G

Rated / Prak Power : 250 / 360 kw

Rated / Peak Torque : 1405 / 2500 Nm

Rated / Peak RPM : 1700 / 3500 RPM TZ380XS016H

Rated / Prak Power : 120 / 240 kw

Rated / Peak Torque : 1200 / 2500 Nm

Rated / Peak RPM : 955 / 3500 RPM TZ380XS016L

Rated / Prak Power : 120 / 240 kw

Rated / Peak Torque : 1200 / 2800 Nm

Rated / Peak RPM : 955 / 3000 RPM TZ380XS029C

Rated / Prak Power : 150 / 240 kw

Rated / Peak Torque : 850 / 1400 Nm

Rated / Peak RPM : 1685 / 5000 RPM TZ380XS029B

Rated / Prak Power : 160 / 270 kw

Rated / Peak Torque : 750 / 1310 Nm

Rated / Peak RPM : 2038 / 5000 RPM TZ380XS024B-II

Rated / Prak Power : 90 / 180 kw

Rated / Peak Torque : 900 / 2100 Nm

Rated / Peak RPM : 955 / 3500 RPM TZ380XS024B-I

Rated / Prak Power : 85 / 170 kw

Rated / Peak Torque : 850 / 1800 Nm

Rated / Peak RPM : 955 / 3500 RPM TZ380XS027C

Rated / Prak Power : 115 / 180 kw

Rated / Peak Torque : 550 / 1200 Nm

Rated / Peak RPM : 2000 / 4000 RPM TZ380XS027B

Rated / Prak Power : 100 / 150 kw

Rated / Peak Torque : 500 / 1000 Nm

Rated / Peak RPM : 1910 / 3500 RPM

Volt : 600 VDC Volt : 618 VDC Volt : 600 VDC Volt : 540 VDC TZ400XS015B

Rated / Prak Power : 250 / 360 kw

Rated / Peak Torque : 1600 / 2500 Nm

Rated / Peak RPM : 1500 / 3500 RPM TZ400XS009A

Rated / Prak Power : 200 / 260 kw

Rated / Peak Torque : 1140 / 3000 Nm

Rated / Peak RPM : 1675 / 3300 RPM TZ400XS013A

Rated / Prak Power : 250 / 410 kw

Rated / Peak Torque : 1750 / 2800 Nm

Rated / Peak RPM : 1364 / 3500 RPM TZ400XS010A

Rated / Prak Power : 100 / 200 kw

Rated / Peak Torque : 1061 / 2500 Nm

Rated / Peak RPM : 900 / 2400 RPM

The relevant products still under developing or waiting to be update, please contact our sales team for latest updates.Products Not Available

Global Activity

SinoMac Makes Its Mark at Global Maritime Event—A Look Back at Marintec China 2025

Hailed as the "Olympics" of the global maritime industry, Marintec China 2025 took place from December 2 to 5, 2025, at the Shanghai New International Expo Centre. Centered on the theme "Innovation and Cooperation for Sustainable Maritime Development," this edition showcased cutting-edge technologies, innovative achievements, and sustainable pathways across the global maritime sector. It attracted over 2,000 exhibiting companies and tens of thousands of professional visitors from more than 100 countries and regions, highlighting China's pivotal influence and open-cooperative stance within the global maritime industry.

SinoMac’s Presence at the 2025 Kazakhstan International Mining, Exploration & Coal Processing Exhibition

As one of the most influential mining exhibitions in Central Asia, the Kazakhstan International Mining, Exploration and Coal Processing Exhibition (Mining Week) was grandly held in Karaganda, Kazakhstan from June 24 to 26, 2025. Focused on the entire mining process, this exhibition showcased a concentrated display of technological innovations, equipment upgrades and green solutions-catering to the industry’s full-chain demands and serving as a premier platform for global mining players to showcase technologies, exchange experience and explore partnerships.

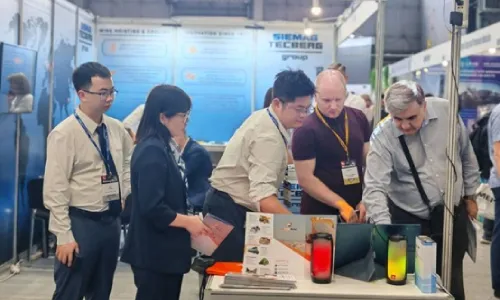

Review of SeaMac 2025 Vietnam International Maritime Ship Exhibition: Deeply connecting with the cutting-edge of the global maritime industry

Recently, the highly anticipated 2025 Vietnam International Maritime and Shipbuilding Exhibition concluded successfully at the Adora Convention Center in Ho Chi Minh City. As Vietnam's largest and most specialized event in shipbuilding and maritime technology, the exhibition gathered top shipbuilders, maritime service providers, and marine equipment manufacturers from around the world. SeaMac actively participated, comprehensively showcasing its innovative achievements and integrated capabilities in ship solutions and high-efficiency propulsion systems. The company engaged in extensive and in-depth exchanges with industry partners, achieving fruitful outcomes from its participation.

Attending a Global Maritime Extravaganza, SinoMac will be showcasing at Marintec China 2025

Marintec China 2025, hailed as a "global trendsetter for the maritime industry," will be held from December 2nd to 5th, 2025, at the Shanghai New International Expo Centre. The theme of this year's exhibition is "Innovation and Cooperation for Sustainable Development of the Maritime Industry," and the theme of the High-Level Maritime Forum is "Intelligent Navigation, Green Coexistence, Integration, and Innovation," reflecting expectations for the industry's future.

Review SAUDI RAIL 2025 :SinoMac Exhibition Highlights

SinoMac successfully participated in SAUDI RAIL 2025, the annual industry event held in Riyadh, Saudi Arabia, from October 19th to 20th, 2025. At the exhibition, SinoMac showcased its strong capabilities in railway technology, innovative solutions, and full lifecycle services, and engaged in in-depth exchanges with industry partners, customers, and experts from around the world to jointly explore future opportunities for rail transit development in the Middle East.

Deeply Cultivate the International Market, Empowering the Future of Rail ——Focus [PRO//Motion Expo 2025]: SinoMac Exhibition Highlights Review

From August 28 to 31, 2025, the highly anticipated PRO//Motion Expo 2025 (Russian International Railway and Motion Exhibition) grandly opened at the Russian Railway Museum in St. Petersburg. PRO//Motion Expo is currently the largest railway and transportation exhibition in Russia and the Commonwealth of Independent States (CIS), attracting extensive participation from railway companies from CIS countries and around the world. Over the four-day exhibition, exhibitors showcased cutting-edge technologies and innovative achievements in the railway transportation industry.

2025 Russian International Railway and Rail Transit Exhibition: SinoMac invites you to join the industry feast

From August 28 to 31, 2025, the highly anticipated biennial Russian International Railway and Rail Transit Exhibition (PRO/Motion Expo) will be held in St. Petersburg. The exhibition is the largest and most professional railway and transportation exhibition in Eastern Europe and Central Asia. PRO/Motion Expo brings together industry elites, corporate representatives and professional visitors from all over the world to witness the latest development achievements and cutting-edge trends in the railway and rail transit industry. Here, many internationally renowned companies will showcase their latest technologies, products and solutions, covering railway infrastructure construction, train manufacturing, communication and signal systems, intelligent transportation and other fields. From advanced train design and manufacturing technology to efficient railway operation and management solutions; from innovative rail material research and development to intelligent railway communication and control systems, various cutting-edge technologies and innovative achievements will be presented one by one, bringing a wonderful industry feast to the participants.

Focus on marine industry event, start a new chapter of marine development together–SinoMac Group Limited to exhibit at Marine & Offshore Vietnam 2025

Against the backdrop of the booming development of the global shipping and maritime industry, Vietnam International Maritime Expo 2025 (Marine & Offshore Vietnam) will be held in Ho Chi Minh City, Vietnam from 19th to 21st November. As one of the most influential maritime events in Southeast Asia, this exhibition brings together top enterprises and innovations in the fields of global shipbuilding, offshore engineering, port equipment, new energy ship technology, etc., and provides an international platform for industry colleagues to exchange and co-operate and explore the market.

SinoMac Group Limited made its debut at the 2025 Indonesia International Construction Machinery, Mining and Concrete Exhibition

The International Exhibition of Engineering Machinery, Mining, and Concrete (Mining Indonesia) will be held in Jakarta, Indonesia, from September 17 to 20, 2025. As one of the most influential mining exhibitions in Southeast Asia, Mining Indonesia provides a professional platform for enterprises, experts, and practitioners in the global mining sector to showcase cutting-edge technologies, exchange industry insights, and explore collaborative opportunities.

SinoMac actively participated in the International Railway and Rail Transit Exhibition in Berlin, Germany, to explore the new future of the industry

From September 22 to 25, 2026, the highly anticipated biennial Berlin International Railway and Rail Transit Exhibition (InnoTrans Berlin) opened grandly in Berlin, Germany. As the largest and most influential event in the global railway and rail transit field, InnoTrans Berlin brings together industry elites, corporate representatives and professional visitors from all over the world to witness the latest development achievements and cutting-edge trends in the railway and rail transit industry. The exhibition covers a number of key areas such as bridges and tunnels, public transportation, and comprehensively displays innovative technologies, advanced equipment and comprehensive solutions in the railway and rail transit industry. From infrastructure construction to operation management, from vehicle manufacturing to intelligent system applications, the exhibition content is rich and diverse, providing participants inside and outside the industry with an excellent platform for a comprehensive understanding of industry dynamics, exchanges and cooperation.