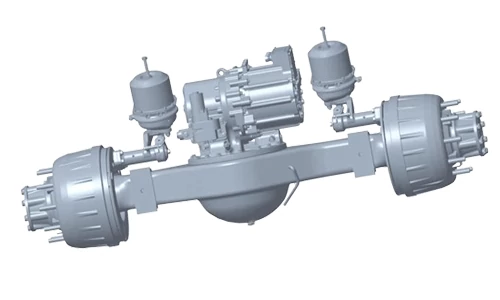

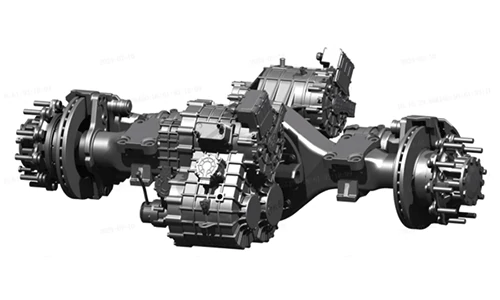

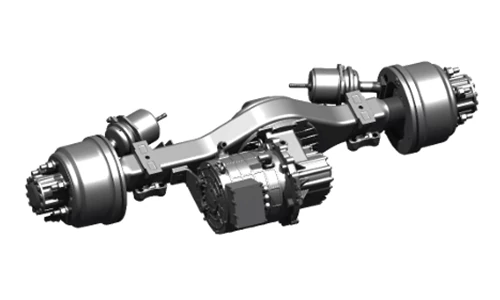

Rated Load : 13000 kg

Maximum Torque : 28000 N.m

Speed Ratio : 54.32 / 18.72

Motor Voltage : 540 V

Electric Driven Alxe

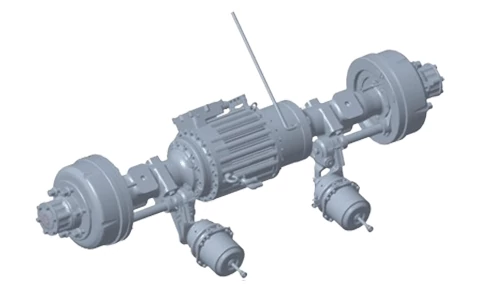

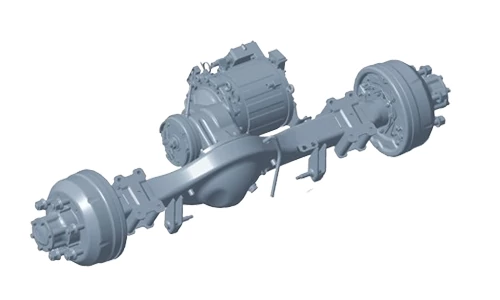

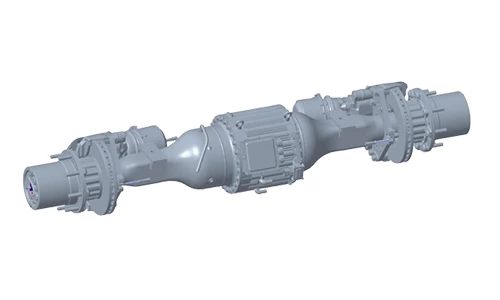

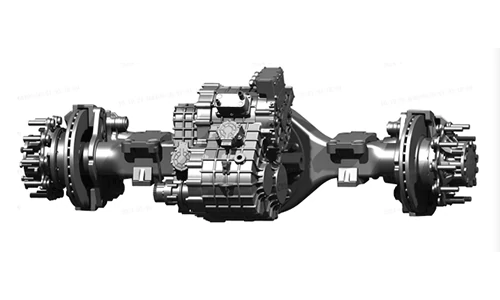

The electric driven axle is a core component of the power system in new energy vehicles. It highly integrates components such as the drive motor, reducer, and differential into the axle, breaking the complex transmission mode of the traditional power system, which is “engine – gearbox – drive shaft – axle”, and achieving direct power transmission with a simple and efficient structure. With advanced electronic control systems, the electric drive axle can precisely regulate power output, intelligently distributing torque to the wheels according to the vehicle’s driving status and road conditions, ensuring stable and efficient operation during starting, acceleration, climbing, and other working conditions. In terms of energy conservation, the energy recovery technology equipped in the electric drive axle can convert the otherwise wasted kinetic energy into electrical energy for recharging the battery during vehicle braking, effectively increasing the driving range. Meanwhile, it produces no exhaust emissions during operation, and noise and vibration are significantly reduced, not only creating a quiet and comfortable environment for drivers and passengers but also aligning with the development trend of green transportation. In terms of application scenarios, electric drive axles are widely suitable for various new energy commercial vehicles such as buses, light trucks, and micro – trucks, playing an important role in urban logistics distribution, public transportation, and other fields, promoting the transportation industry towards a cleaner, smarter, and more efficient direction.

Advantages of Electric Driven Alex

- High reliability: Due to the integrated design, many transmission components are reduced, which decreases the connection loss and failure points between components. As a result, the overall reliability of the electric drive axle is significantly improved, reducing vehicle downtime caused by power system failures and ensuring transportation efficiency.

- Strong adaptability: The electric drive axle can flexibly adjust parameters such as motor power and torque output characteristics according to the requirements of different vehicle models. Whether it is a heavy – duty transport vehicle with high power requirements or a small vehicle pursuing energy – saving and portability, it can achieve good adaptation, expanding the product application range.

- High degree of intelligence: With the help of advanced sensors and intelligent algorithms, the electric drive axle can monitor its own operating status and vehicle conditions in real – time, conduct automatic fault diagnosis and early warning. It can also be deeply integrated with the vehicle’s intelligent driving system, providing stable power support for autonomous driving functions.

The truck electric drive system revolutionizes the traditional fuel-powered model, utilizing advanced electric motors and battery packs as the core power source. Through a sophisticated electronic control unit that adjusts the current in real-time, the electric motor can instantly deliver high torque, enabling rapid starts and efficient acceleration. The CRRC Zhuzhou 1435 series dual rail sightseeing car inherits the technological DNA of CRRC high-speed rail and is designed for in-depth sightseeing in scenic areas. The innovative double-decker structure features a panoramic window on the first floor for comfortable all-weather sightseeing and an open-top layout on the second floor for a 360° immersive natural experience. CHSR's CHSR™ CC750 air-cooled converter is a highly integrated traction and auxiliary "two-in-one" core equipment. It condenses key power conversion functions into a single compact enclosure, providing robust and stable power for intercity trains through standardized modular design, intelligent air cooling (IP65 protection), and mature and reliable components. CRRC Braking Systems Co., Ltd.'s disc brake calipers use hydraulic or pneumatic-hydraulic conversion drive technology.They integrate automatic gap adjustment, modular caliper body, and three-point floating suspension design to ensure precise contact between brake pads and discs. RailMac provides railway solutions, focusing on one-stop Lince/Huanji wiper services (R&D, production, maintenance) plus rail air conditioning. It offers diverse wipers (DC110V/74V/24V, pneumatic) and developed China’s first IP-owned CRH3 EMU wiper, with products batch-loaded in CRH380/CR400BF/CR300BF. RunWell is a high-tech enterprise specializing in the fields of rail transit and military industry. Its car lift machine products integrate German drive technology (such as the Demag three-in-one modular system) with intelligent control, supporting heavy-duty conditions of over 150 tons. CRRC specializes in innovative environmental protection sanitation systems. Products like vacuum water - saving toilet modules and waterless ecological toilets, made in an orderly factory, are applied in railways, public facilities, and outdoor scenarios. Partnering with global leaders, RailMac offers superior railway equipment and solutions at competitive prices. It hit milestones like Thailand’s 2017 first local train, pioneered SEA new energy trains, and joined Russia’s high-speed rail project, boosting its railway industry presence.Truck Electric Drive Axle

Tourist Train

Traction System

Bogie and Braking System

Track Body Components

Maintenance Equipment

Railway Components

RailMac

Find Electric Driven Alxe by Series

This is the list of all series of Electric Driven Alxe.

Click here to find Electric Driven Alxe by type.

| 3500 – 13000 kg | ||||||||

| 3500 – 13000 kg | ||||||||

| 2 – 13 T | ||||||||

Engine Model Load/kg | 0 | 2000 | 4000 | 8000 | 10000 | 12000 | 14000 | 16000 |

| Electric Driven Alxe Catalogue | ||||||||

Rated Load : 3500 kg Rated Load : 3500 kg EP-Axle6 Truck

Maximum Torque : 5700 N.m

Speed Ratio : 16.5

Motor Voltage : 360 / 540 V EP-Axle5 Truck

Maximum Torque : 5400 N.m

Speed Ratio : 15.58

Motor Voltage : 360 / 540 V

Rated Load : 13000 kg Rated Load : 13000 kg Rated Load : 8500 kg Rated Load : 3500 kg Rated Load : 3500 kg EP-Axle19C2 Passenger Car

Maximum Torque : 19256 N.m

Speed Ratio : 25.338

Motor Voltage : 540 V EP-Axle19C Passenger Car

Maximum Torque : 18000 N.m

Speed Ratio : 20.05

Motor Voltage : 650 / 576 V EP-Axle13 Passenger Car

Maximum Torque : 13000 N.m

Speed Ratio : 19.89

Motor Voltage : 380 V EP-Axle6 Passenger Car

Maximum Torque : 5700 N.m

Speed Ratio : 16.5

Motor Voltage : 360 / 540 V EP-Axle5 Passenger Car

Maximum Torque : 5400 N.m

Speed Ratio : 15.58

Motor Voltage : 360 / 540 V

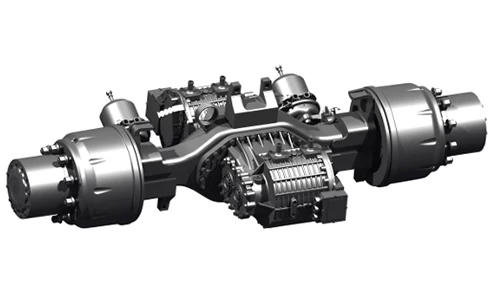

Rated Axle Load : 13 T Rated Axle Load : 13 T Rated Axle Load : 11.5 ~ 13 T Rated Axle Load : 11.5 T Rated Axle Load : 11.5 T Rated Axle Load : 8 T Rated Axle Load : 6 T Rated Axle Load : 6 T Rated Axle Load : 3.5 ~ 4.5 T Rated Axle Load : 3 T Rated Axle Load : 2 T QT130SPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1054 mm

Total Speed Ratio : 56.7 / 23.5 / 46 / 19 QT130STPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1040 mm

Total Speed Ratio : 56.6 / 32 / 16.7 QT115SPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1040 mm

Total Speed Ratio : 75 / 38 / 20.8 QT115DTPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1040 mm

Total Speed Ratio : 14.5 QT115TPE

End Face Distance : 1860 mm

Leaf Spring Distance : 1030 mm

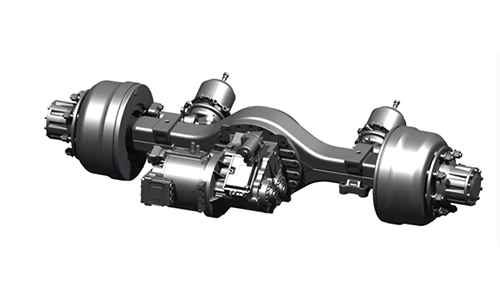

Total Speed Ratio : 14.5 QT80SPE

End Face Distance : 1804 mm

Leaf Spring Distance : 1030 mm

Total Speed Ratio : 31.1 / 16.3 QT60SPE

End Face Distance : 1615 mm

Leaf Spring Distance : 940 mm

Total Speed Ratio : 28.202 / 11.379 QT60PE

End Face Distance : 1615 mm

Leaf Spring Distance : 940 mm

Total Speed Ratio : 16.5 QT30-45PE

End Face Distance : 1640 ~ 1495 mm

Leaf Spring Distance : 920 / 970 mm

Total Speed Ratio : 16.1 QT30PE

End Face Distance : 1470 mm

Leaf Spring Distance : 900 mm

Total Speed Ratio : 14.3 QT20PE

End Face Distance : 1535 mm

Leaf Spring Distance : 1080 mm

Total Speed Ratio : 14

Global Activity

SinoMac Makes Its Mark at Global Maritime Event—A Look Back at Marintec China 2025

Hailed as the "Olympics" of the global maritime industry, Marintec China 2025 took place from December 2 to 5, 2025, at the Shanghai New International Expo Centre. Centered on the theme "Innovation and Cooperation for Sustainable Maritime Development," this edition showcased cutting-edge technologies, innovative achievements, and sustainable pathways across the global maritime sector. It attracted over 2,000 exhibiting companies and tens of thousands of professional visitors from more than 100 countries and regions, highlighting China's pivotal influence and open-cooperative stance within the global maritime industry.

SinoMac’s Presence at the 2025 Kazakhstan International Mining, Exploration & Coal Processing Exhibition

As one of the most influential mining exhibitions in Central Asia, the Kazakhstan International Mining, Exploration and Coal Processing Exhibition (Mining Week) was grandly held in Karaganda, Kazakhstan from June 24 to 26, 2025. Focused on the entire mining process, this exhibition showcased a concentrated display of technological innovations, equipment upgrades and green solutions-catering to the industry’s full-chain demands and serving as a premier platform for global mining players to showcase technologies, exchange experience and explore partnerships.

Review of SeaMac 2025 Vietnam International Maritime Ship Exhibition: Deeply connecting with the cutting-edge of the global maritime industry

Recently, the highly anticipated 2025 Vietnam International Maritime and Shipbuilding Exhibition concluded successfully at the Adora Convention Center in Ho Chi Minh City. As Vietnam's largest and most specialized event in shipbuilding and maritime technology, the exhibition gathered top shipbuilders, maritime service providers, and marine equipment manufacturers from around the world. SeaMac actively participated, comprehensively showcasing its innovative achievements and integrated capabilities in ship solutions and high-efficiency propulsion systems. The company engaged in extensive and in-depth exchanges with industry partners, achieving fruitful outcomes from its participation.

Attending a Global Maritime Extravaganza, SinoMac will be showcasing at Marintec China 2025

Marintec China 2025, hailed as a "global trendsetter for the maritime industry," will be held from December 2nd to 5th, 2025, at the Shanghai New International Expo Centre. The theme of this year's exhibition is "Innovation and Cooperation for Sustainable Development of the Maritime Industry," and the theme of the High-Level Maritime Forum is "Intelligent Navigation, Green Coexistence, Integration, and Innovation," reflecting expectations for the industry's future.

Review SAUDI RAIL 2025 :SinoMac Exhibition Highlights

SinoMac successfully participated in SAUDI RAIL 2025, the annual industry event held in Riyadh, Saudi Arabia, from October 19th to 20th, 2025. At the exhibition, SinoMac showcased its strong capabilities in railway technology, innovative solutions, and full lifecycle services, and engaged in in-depth exchanges with industry partners, customers, and experts from around the world to jointly explore future opportunities for rail transit development in the Middle East.

Deeply Cultivate the International Market, Empowering the Future of Rail ——Focus [PRO//Motion Expo 2025]: SinoMac Exhibition Highlights Review

From August 28 to 31, 2025, the highly anticipated PRO//Motion Expo 2025 (Russian International Railway and Motion Exhibition) grandly opened at the Russian Railway Museum in St. Petersburg. PRO//Motion Expo is currently the largest railway and transportation exhibition in Russia and the Commonwealth of Independent States (CIS), attracting extensive participation from railway companies from CIS countries and around the world. Over the four-day exhibition, exhibitors showcased cutting-edge technologies and innovative achievements in the railway transportation industry.

2025 Russian International Railway and Rail Transit Exhibition: SinoMac invites you to join the industry feast

From August 28 to 31, 2025, the highly anticipated biennial Russian International Railway and Rail Transit Exhibition (PRO/Motion Expo) will be held in St. Petersburg. The exhibition is the largest and most professional railway and transportation exhibition in Eastern Europe and Central Asia. PRO/Motion Expo brings together industry elites, corporate representatives and professional visitors from all over the world to witness the latest development achievements and cutting-edge trends in the railway and rail transit industry. Here, many internationally renowned companies will showcase their latest technologies, products and solutions, covering railway infrastructure construction, train manufacturing, communication and signal systems, intelligent transportation and other fields. From advanced train design and manufacturing technology to efficient railway operation and management solutions; from innovative rail material research and development to intelligent railway communication and control systems, various cutting-edge technologies and innovative achievements will be presented one by one, bringing a wonderful industry feast to the participants.

Focus on marine industry event, start a new chapter of marine development together–SinoMac Group Limited to exhibit at Marine & Offshore Vietnam 2025

Against the backdrop of the booming development of the global shipping and maritime industry, Vietnam International Maritime Expo 2025 (Marine & Offshore Vietnam) will be held in Ho Chi Minh City, Vietnam from 19th to 21st November. As one of the most influential maritime events in Southeast Asia, this exhibition brings together top enterprises and innovations in the fields of global shipbuilding, offshore engineering, port equipment, new energy ship technology, etc., and provides an international platform for industry colleagues to exchange and co-operate and explore the market.

SinoMac Group Limited made its debut at the 2025 Indonesia International Construction Machinery, Mining and Concrete Exhibition

The International Exhibition of Engineering Machinery, Mining, and Concrete (Mining Indonesia) will be held in Jakarta, Indonesia, from September 17 to 20, 2025. As one of the most influential mining exhibitions in Southeast Asia, Mining Indonesia provides a professional platform for enterprises, experts, and practitioners in the global mining sector to showcase cutting-edge technologies, exchange industry insights, and explore collaborative opportunities.

SinoMac actively participated in the International Railway and Rail Transit Exhibition in Berlin, Germany, to explore the new future of the industry

From September 22 to 25, 2026, the highly anticipated biennial Berlin International Railway and Rail Transit Exhibition (InnoTrans Berlin) opened grandly in Berlin, Germany. As the largest and most influential event in the global railway and rail transit field, InnoTrans Berlin brings together industry elites, corporate representatives and professional visitors from all over the world to witness the latest development achievements and cutting-edge trends in the railway and rail transit industry. The exhibition covers a number of key areas such as bridges and tunnels, public transportation, and comprehensively displays innovative technologies, advanced equipment and comprehensive solutions in the railway and rail transit industry. From infrastructure construction to operation management, from vehicle manufacturing to intelligent system applications, the exhibition content is rich and diverse, providing participants inside and outside the industry with an excellent platform for a comprehensive understanding of industry dynamics, exchanges and cooperation.